| Dehumidifying dryers Details description |

|

| product name:Dehumidifying dryers |

| release time:2020-11-02 |

| Numbering:Dehumidifying dryer |

| Brand:wto-btb |

| Price:¥By function |

| weight :By function |

| unit weight:Kg/set |

manufacturer:wto-btb |

| patent:wto-btb |

| Producing country: |

simple description:Dehumidifying dryer,

This is a device used to dehumidifying plastic resin to

achieve drying. For example,POM,ABS,TPE,PAL,ABS,CAB,

EVA(2),EVOH,LM(4),LCP,PA11,PA6.46.6,PAI,PAR,PBT,

PC,PC/ABS,PC/PBT,PE.HDEPE,LDPE black3%,PE.HDEPE.

LDPE black40%,PEEK,PE(1),PEN,PES,PET,PETG,PI,

PMMA,POM,PP,PPO,PPS,PS,[GPPS.EPS.HIPS],PSU,

PIT,PUR,PVC,SAN,SB,TPE,TPE,TPO,TPU,

Dehumidifier dryer and other plastic resins must be

dehumidified and dried during the production process to

improve the quality of the finished product. |

| Product alias:Dehumidifying dryer |

|

| Dehumidifying dryers Product introduction |

|

Dehumidifying dryers parameter

Dehumidifying dryer

| Model |

Capacity (KG) |

HeatingPower

(KW) |

Blower

(W) |

Power

(V) |

Dimensions

(HxWxD,MM) |

Approx.Net Weight

(KG) |

| HGB-6 |

6 |

1.5 |

150 |

1φ 220V |

490x490x785 |

25 |

| HGB-12 |

12 |

2 |

160 |

1φ 220V |

540x435x850 |

35 |

| HGB-25 |

25 |

3 |

150 |

1φ 220V |

605x560x1240 |

50 |

| HGB-50 |

50 |

3.9 |

160 |

3φ 380V |

706x594x1410 |

75 |

| HGB-75 |

75 |

4.2 |

240 |

3φ 380V |

751x649x1520 |

105 |

| HGB-100 |

100 |

6.2 |

240 |

3φ 380V |

817x581x1670 |

125 |

| HGB-150 |

150 |

7 |

240 |

3φ 380V |

868x710x1800 |

160 |

| HGB-200 |

200 |

11 |

300 |

3φ 380V |

995x830x1930 |

210 |

| HGB-300 |

300 |

18 |

320 |

3φ 380V |

1160x975x2280 |

330 |

| HGB-400 |

400 |

20 |

360 |

3φ 380V |

1220x990x2330 |

365 |

| HGB-500 |

500 |

22 |

750 |

3φ 380V |

1150x1045x2430 |

385 |

| HGB-600 |

600 |

24 |

750 |

3φ 380V |

1210x1070x2540 |

400 |

| HGB-800 |

800 |

30 |

1500 |

3φ 380V |

1390x1120x2730 |

600 |

| HGB-1000 |

1000 |

36 |

1500 |

3φ 380V |

1525x1425x3670 |

650 |

| HGB-1200 |

1200 |

36 |

1500 |

3φ 380V |

1600x1510x3722 |

835 |

| HGB-1500 |

1500 |

40 |

2200 |

3φ 380V |

1730x1680x3880 |

900 |

| HGB-1800 |

1800 |

45 |

2200 |

3φ 380V |

1835x1680x4060 |

1005 |

| HGB-2000 |

2000 |

45 |

2200 |

3φ 380V |

1870x1710x4415 |

1130 |

| HGB-3000 |

3000 |

50 |

3700 |

3φ 380V |

2080x1920x4520 |

1650 |

| HGB-3500 |

3500 |

50 |

3700 |

3φ 380V |

2141x1976x4863 |

2120 |

| HGB-4000 |

4000 |

60 |

3700 |

3φ 380V |

2192x2040x4936 |

2870 |

| HGB-5000 |

5000 |

60 |

5500 |

3φ 380V |

2355x2160x5120 |

3510 |

Product alias:Dehumidifying dryer,Dehumidifying dryers |

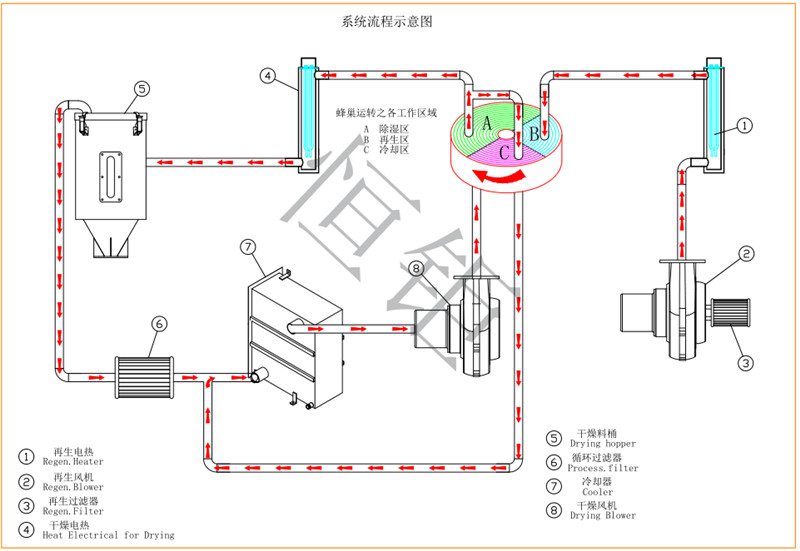

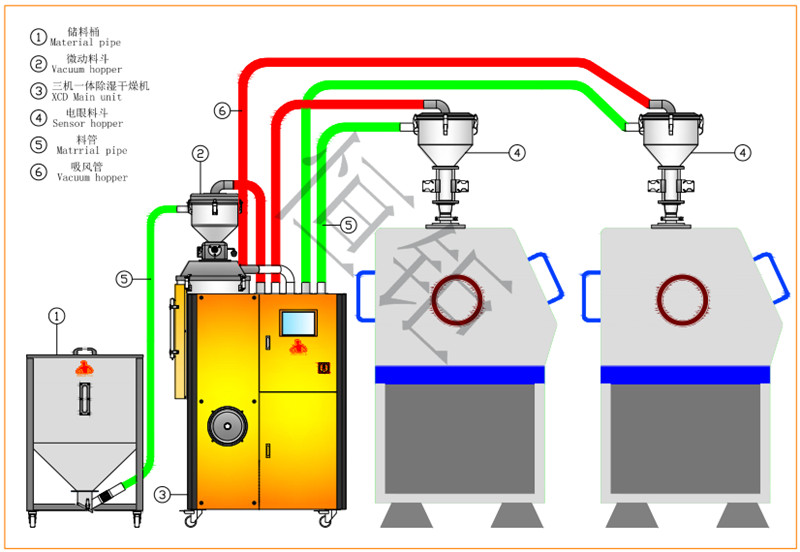

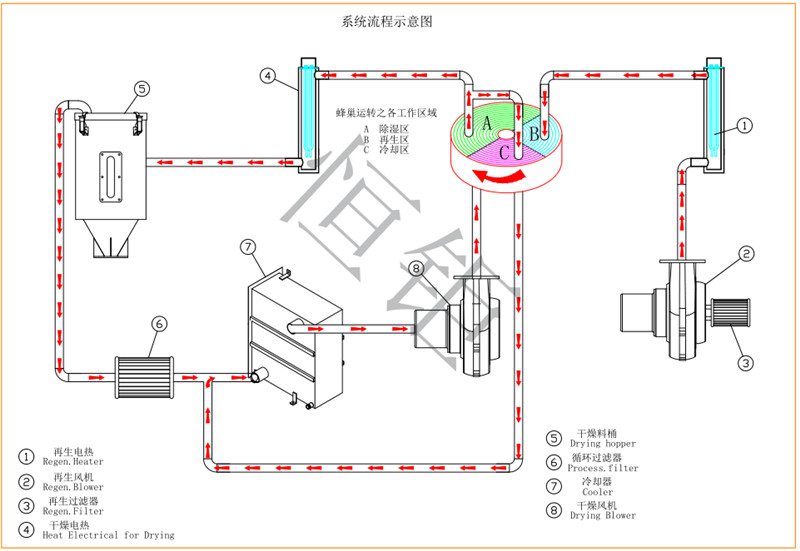

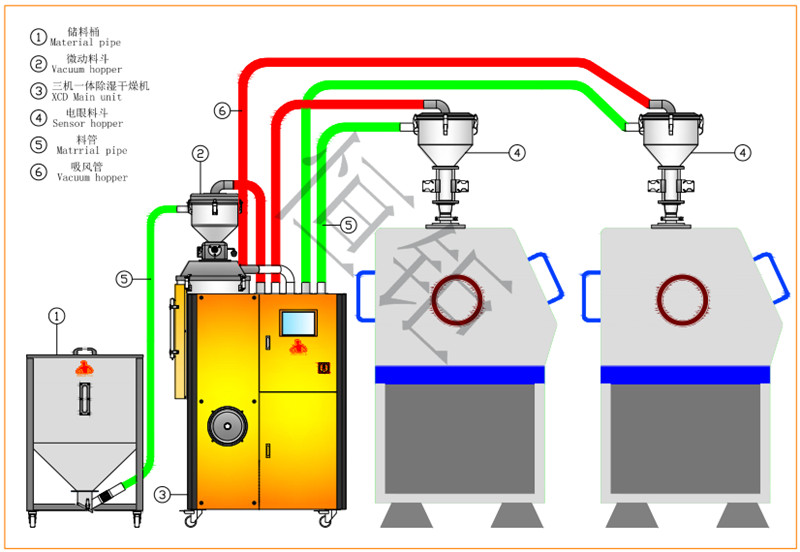

Dehumidifying dryers Equipment principle

Plastics are polymer compounds made by polymerization of monomers as raw materials through addition polymerization or condensation polymerization. Plastic has the advantages of strong corrosion resistance, no reaction with acid and alkali, low manufacturing cost, durability, waterproof, light weight, and easy to be molded into different shapes, so it is widely used in agriculture, machinery industry, chemical industry, and defense industry. It has become one of the indispensable products in life. However, because plastics are not easily degraded, the environmental pollution caused by them is also very serious, so now a large number of plastic recycling companies have emerged.

When plastics are recycled, they generally need to go through multiple steps such as sorting, cleaning, crushing, drying, and melting. Most waste plastics are stained with paints, slag, etc., so they must be cleaned and dried. However, the amount of plastic cleaning and drying is relatively large. The effect of centralized cleaning is better, but the effect of centralized drying is not good. It is located in the middle The plastic is not easy to be dried. In summary, there is a need for a plastic dryer with good drying effect.

Elements:

Plastic dryer to solve the problem of poor drying effect of the intermediate plastic when the plastic is intensively dried.

In order to achieve the above purpose, we provide related solutions: a plastic dryer, including a feeding box, a frame and a motor, the feeding box is fixed on the frame, the upper end of the feeding box is provided with a feeding port, and the motor is fixed The output end of the motor is arranged horizontally on the frame, the output end of the motor extends horizontally into the feeding box, the output end of the motor is provided with a first fan blade, and the side wall of the feeding box is connected with The spiral tube is arranged horizontally, the end of the spiral tube close to the first fan blade is aligned with the first fan blade, the upper end of the spiral tube is provided with a powder inlet, the powder inlet is connected with a valve, and the upper end of the valve is connected with a drying box. The spiral tube is also provided with a number of powder outlets. The position of the powder outlet is far away from the end of the spiral tube that communicates with the feeding box. There are concentric annular openings on the spiral tube. The annular opening is connected to the rotating ring for rotation. The ring and the annular opening are sealed in rotation. The inner wall of the rotating ring is provided with elastic strips or brushes. The elastic strips or brushes are arranged along the radial direction of the rotating ring. The outer ring of the rotating ring is coaxially provided with a worm gear. The motor The output end is provided with a first gear, a gear shaft is rotatably connected to the frame, a second gear is provided on the gear shaft, and the second gear meshes with the first gear. The gear shaft is also provided with a worm coaxially, and the worm wheel and The worm meshes. Dehumidifying dryers It adopts double condenser structure to ensure lower return air temperature and dew point.

1. Dehumidifying dryers Adopt P.I.D temperature control system, which has regeneration temperature setting and actual temperature display screen.

2. Adjustable rotating speed control of honeycomb wheel.

3. The honeycomb can reach a dew point of -40°C, and can reach a dew point of -50°C or even lower when the configuration is enhanced.

4. Optional PLC control with LCD touch man-machine interface.

5. Dew point meter that can monitor the dehumidification effect of the machine at any time is optional.

6. The machine occupies a small area and is easy to move, and the machine can be replaced at will.

Product alias:Dehumidifying dryer |

Dehumidifying dryers application

The working principle of this basic solution is: pour the cleaned and crushed plastic into the feeding box, start the motor, and the motor drives the first fan to rotate. When the first fan rotates, a large amount of airflow is generated, and the airflow gradually removes all plastic Blow into the spiral tube. Open the valve, the dry powder falls into the spiral tube, the airflow will blow the dry powder and the plastic at the same time, when the absorbent powder comes in contact with the water on the plastic, it will absorb the moisture. The output end of the motor can also drive the first gear to rotate, the first gear drives the second gear to rotate, the second gear drives the gear shaft and the worm on the gear shaft to rotate, the worm drives the worm wheel to rotate, and the worm wheel drives the rotating ring to rotate. When the plastic passes through the rotating ring with elastic strips, the elastic strips in the rotating ring will brush to the plastic and make the plastic rotate to change the direction, so that every surface of the plastic can contact with the dry powder and get dried. When the plastic passes through the rotating ring with a brush, the brush can brush off the dry powder contaminated on the plastic, and separate the plastic from the dry powder. When the dry powder is blown near the powder outlet, since the diameter of the powder outlet is smaller than the plastic, the dry powder will flow out of the powder outlet.

The beneficial effects of this basic solution are:

1. In this solution, the airflow generated by the first fan blade is used to blow the plastic and blow the plastic into the spiral tube. Due to the long path of the spiral tube, the plastic will be blown by the airflow for a long time, and the airflow can blow the spiral. The water on the pipe blows away.

2. In the prior art, when the plastic is intensively dried, the drying effect of the intermediate plastic is not good. In this solution, the plastic does not enter the spiral tube at the same time, but is gradually blown into the spiral tube by the airflow, so the airflow can contact all the plastics and blow down the water on the plastics, and all the plastics can be obtained. dry.

3. After pouring the dry powder into the powder inlet, the dry powder can absorb the water on the plastic surface after contacting with the plastic, and not all the plastic enters the spiral tube at the same time, but the plastic is blown into the spiral tube successively. Therefore, as long as the dry powder is continuously added to the powder inlet, the dry powder can adhere to and dry all the plastics.

4. Although the drying effect of the dry powder is good, it is not easy to fall off when it is attached to the plastic. In this solution, when the plastic passes through the rotating ring with the brush, the brush can brush off the dry powder on the plastic and separate the dry powder from the plastic.

Further, a heating device is provided in the feeding box. With this solution, after the airflow formed by the rotation of the first fan blade is heated, the airflow has a better drying effect on the plastic.

Further, a cloth bag is sleeved on the powder outlet. With this scheme, the dry powder will fall into the cloth bag after falling out of the powder outlet.

Further, the dry powder is a water-absorbing resin. The water-absorbing resin has good water absorption properties and can be reused.

Further, the spiral tube is provided with a collection box at one end away from the feed box. The collection box is used to collect the dried plastic.

Further, the bottom of the collection box is provided with a number of springs, the top of the springs is detachably connected with a number of collection plates, the collection plates are slidably connected to the inner wall of the collection box, the collection plates are provided with a number of screen holes, and the collection box rotates. A fan blade rod is connected, and a second fan blade and a cam are coaxially provided on the fan blade rod. The second fan blade is aligned with one end of the spiral tube away from the feeding box, and the cam abuts against the collecting plate. When the plastic enters the collection box, it will inevitably be contaminated with some dry powder. With this solution, when the airflow flows out of the spiral tube, the second fan blade will be blown. The second fan blade drives the cam to rotate. The cam drives the collecting plate to vibrate up and down, and the collecting plate drives the plastic to vibrate. The dry powder on the plastic will vibrate and pass through. The sieve enters the bottom of the collection box.

In the specific implementation, the cleaned and crushed plastic is put into the feeding box 2 from the feeding port 3, the motor 4 and the heating wire are started, and the valve is opened. After the first fan blade 20 rotates, an air flow is generated. The air flow is heated by the heating wire, and the air flow blows the plastic into the spiral tube 8 and heats and drys it. After the valve is opened, the water-absorbent resin falls into the spiral tube 8 and is contaminated on the plastic, and the plastic is absorbed and dried. At the same time, the airflow blows the plastic and the water-absorbent resin to continue moving in the spiral tube 8. The first gear 5 on the motor 4 drives the second gear 6 to rotate, the second gear 6 drives the worm gear 9 and the worm 10 to rotate, and the worm gear 9 drives the rotating ring 18 to rotate. When the plastic passes through the rotating ring 18 on the left, the plastic rotates under the action of the elastic strip 19 so that all surfaces of the plastic can contact with the water-absorbing resin. When the plastic passes through the rotating ring 18 on the right, the water-absorbing resin on the plastic will be brushed off by the brush. Most of the water absorbing resin can pass through the screen and enter the cloth bag 11 when passing through the powder outlet. The plastic continues to move in the spiral tube 8 and finally enters the collection box 12. When the airflow enters the collection box 12 from the spiral tube 8, the airflow will blow the second fan blade 16. The second fan blade 16 drives the fan rod 15 to rotate, the fan rod 15 drives the cam 17 to rotate, and the cam 17 drives the collecting plate 13 Vibration, the collection plate 13 drives the plastic to vibrate, and the water-absorbing particles on the plastic will be shaken down and pass through the sieve holes on the collection plate 13, and finally fall to the bottom of the collection box 12.

1. Foundry industry:

In this process, the wax mold is repeatedly immersed in the clay. These outer layers form the mold. When the wax is melted, the molten metal can be poured into it. Dry air (very low vapor pressure) is better than others. The heating source is more commonly used to dry the clay layer, because the dry air will not deform the wax mold. The use of a hygroscopic dehumidifier can stabilize the operating cost of foundries in the foundry industry and increase the production volume without slowing down the production pace in the wet months, and the process drying time can be shortened by 50%.

2. Dehumidification and drying of plastic raw material resin:

All plastic raw material resins have a certain degree of hygroscopicity. When the plastic raw material particles are extruded, the moisture is heated and evaporated by the plastic raw material dehumidifier. These vapors will cause cracks in the structure and appearance of the plastic material. The desiccant dryer can reduce the humidity in the plastic raw materials and improve the quality of the finished product.

Dehumidifying dryers;This is a device used to dehumidifying plastic resin to achieve drying. For example,

POM,ABS,TPE,PAL,ABS,CAB,EVA(2),EVOH,LM(4),LCP,PA11,PA6.46.6,PAI,PAR,PBT,

PC,PC/ABS,PC/PBT,PE.HDEPE,LDPE black3%,PE.HDEPE.LDPE black40%,PEEK,PE(1),

PEN,PES,PET,PETG,PI,PMMA,POM,PP,PPO,PPS,PS,[GPPS.EPS.HIPS],PSU,PIT,PUR,

PVC,SAN,SB,TPE,TPE,TPO,TPU,

Dehumidifier dryerand other plastic resins must be dehumidified and dried during the production process to improve the quality of the finished product.

Product alias:Dehumidifying dryer,Dehumidifying dryers |

Dehumidifying dryers Precautions

1. Precautions for operation of desiccant dryer:

1.) Make sure that the dehumidification dryer has been installed and adjusted;

2. )Turn on the power switch on the control box power supply and the dehumidifier panel;

3. )Check the temperature indication of the material barrel frequently, and repair it in time if any malfunction is found;

4. )When the temperature rises to the specified temperature, check whether it is consistent with the temperature of the lower part;

5. )Keep the barrel full at any time during production;

6. )The raw materials can be produced only after the specified drying time is fully reached;

7. )When the drying is completed, when the machine is to be shut down, close the feeding plate first, and then close the feeding system after pumping the bottom raw materials.

2. Maintenance of dehumidification dryer:1. )Please confirm to provide cooling circulating water before machine operation;

2. )Regularly clean the dehumidification return air aluminum mesh and the recycled motor aluminum mesh;

3. )Regularly check whether the pipeline is damaged, loose, or dew;

4. )Regularly check whether the floating belt is worn.

Dehumidifying dryers Maintenance:

1. Dehumidifying dryersCheck the parts regularly, 1-2 times a month. The inspection items are whether the worm, bearing, shaft seal and other movable parts are flexible in rotation and wear. Any defects should be repaired in time for normal use.

2.Dehumidifying dryers Electrical control parts should be kept clean and sensitive, and faults should be repaired in time.

3.Dehumidifying dryers When one use is completed or work is stopped, the remaining materials should be taken out of the plastic drying and mixing machine, and the remaining powder in each part of the machine should be cleaned. If it is out of service for a long time, the machine must be wiped clean and covered with a tarp cloth.

4.Dehumidifying dryers When assembling and disassembling the mixing paddle of the plastic drying color mixing machine, it should be disassembled, steadily installed, and handled gently to avoid deformation and damage.

Correct operation for Dehumidifying dryers:![Dehumidifying dryers,Dehumidifying dryer,POM,ABS,TPE,PAL,ABS,CAB,EVA(2),EVOH,LM(4),LCP,PA11,PA6.46.6,PAI,PAR,PBT,PC,PC/ABS,PC/PBT,PE.HDEPE,LDPE black3%,PE.HDEPE.LDPE black40%,PEEK,PE(1),PEN,PES,PET,PETG,PI,PMMA,POM,PP,PPO,PPS,PS,[GPPS.EPS.HIPS],PSU,PIT,PUR,PVC,SAN,SB,TPE,TPE,TPO,TPU,Dehumidifying dryers](/d/file/p/2020/11-02/b30cd8100fb7e36530209b421f6abc5a.gif) 1. Before starting up, check the power distribution of all equipment and pipelines before work. If there are hidden dangers, remove them and deal with them in time.

2. Clean the air inlet filter of the heater.

3. When the temperature of the imported heat transfer oil of the main engine rises to 100-120℃, the induced air can be started.

4. The inlet temperature of the cloth bag can reach 70℃ or higher, which can be opened for stirring, stirring, and the number of rotations is appropriate.

5. Air pressure: main machine inlet 6-10Mpa, cloth bag inlet, main machine outlet 20-26Mpa, cloth bag outlet 36-40Mpa.

6. Unloading will start within 15 minutes when the machine is turned on and the unloading cannot be stopped for any reason, until the material in the bag box is unloaded after the machine stops.

7. Each shift must have a special person to watch the instrument on the panel, and if there is an abnormality, and find it out in time, the watcher can not leave without authorization until the machine stops.

8. The feeding personnel should carefully observe the material during feeding to avoid foreign matter in the material and cause accidents.

9. In normal work, the temperature of the heat transfer oil inlet cannot exceed 250°C, otherwise it will be opened and closed immediately to cool down.

10. When you hear noise in the host during work, stop it immediately, open the side door of the host, cool down and use a magnetic stick or touch it to clean out the foreign objects.

11. When the power is cut off during work, immediately close the thermal oil valve, open and close, and open the side door of the main engine to cool down.

12.Dehumidifying dryers When the power is cut, the cloth bag should be cleaned first. When the induced air is turned on, open the side door of the main unit to observe whether there is sparks. If necessary, spray with water (mist).

13. If there is a sudden change in the radiator oil bag pipeline (severe oil leakage, fire, etc.), the main oil guide valve should be closed immediately, and on-site fire fighting should be carried out immediately, and the boiler should be notified to cool down.

14. If sparks and explosions are found on the main engine and the bag box, immediately stop the induced air, open the closed valve, and close the valve of the main oil pipeline.

15. When you find sparks in the bag, take the time to unwind the material that is on fire, flush the bag with water, and control the amount of water to prevent the bag from being damaged even if the water level is too high.

16. Dehumidifying dryers Operators must keep a clear head when they are on the job, and keep patrolling and checking and not leaving the job without permission.

1. Before starting up, check the power distribution of all equipment and pipelines before work. If there are hidden dangers, remove them and deal with them in time.

2. Clean the air inlet filter of the heater.

3. When the temperature of the imported heat transfer oil of the main engine rises to 100-120℃, the induced air can be started.

4. The inlet temperature of the cloth bag can reach 70℃ or higher, which can be opened for stirring, stirring, and the number of rotations is appropriate.

5. Air pressure: main machine inlet 6-10Mpa, cloth bag inlet, main machine outlet 20-26Mpa, cloth bag outlet 36-40Mpa.

6. Unloading will start within 15 minutes when the machine is turned on and the unloading cannot be stopped for any reason, until the material in the bag box is unloaded after the machine stops.

7. Each shift must have a special person to watch the instrument on the panel, and if there is an abnormality, and find it out in time, the watcher can not leave without authorization until the machine stops.

8. The feeding personnel should carefully observe the material during feeding to avoid foreign matter in the material and cause accidents.

9. In normal work, the temperature of the heat transfer oil inlet cannot exceed 250°C, otherwise it will be opened and closed immediately to cool down.

10. When you hear noise in the host during work, stop it immediately, open the side door of the host, cool down and use a magnetic stick or touch it to clean out the foreign objects.

11. When the power is cut off during work, immediately close the thermal oil valve, open and close, and open the side door of the main engine to cool down.

12.Dehumidifying dryers When the power is cut, the cloth bag should be cleaned first. When the induced air is turned on, open the side door of the main unit to observe whether there is sparks. If necessary, spray with water (mist).

13. If there is a sudden change in the radiator oil bag pipeline (severe oil leakage, fire, etc.), the main oil guide valve should be closed immediately, and on-site fire fighting should be carried out immediately, and the boiler should be notified to cool down.

14. If sparks and explosions are found on the main engine and the bag box, immediately stop the induced air, open the closed valve, and close the valve of the main oil pipeline.

15. When you find sparks in the bag, take the time to unwind the material that is on fire, flush the bag with water, and control the amount of water to prevent the bag from being damaged even if the water level is too high.

16. Dehumidifying dryers Operators must keep a clear head when they are on the job, and keep patrolling and checking and not leaving the job without permission.

Product alias:Dehumidifying dryer,Dehumidifying dryers |

|

|

+8613669807274

+8613669807274

+8613669807274

+8613669807274 wto-btb@wto-btb.com

wto-btb@wto-btb.com Tel: +8613669807274

Tel: +8613669807274 SMS: +8613669807274

SMS: +8613669807274