| 3 in 1 Dehumidifying Dryer Details description |

|

| product name:3 in 1 Dehumidifying Dryer |

| release time:2020-09-16 |

| Numbering:3 in 1 plastic desiccant dryer |

| Brand:wto-btb |

| Price:¥By function |

| weight :By function |

| unit weight:Kg/set |

manufacturer:wto-btb |

| patent:wto-btb |

| Producing country:china |

| simple description:3 in 1 plastic desiccant dryer,plastic dehumidifying dryer,PET,PE,PC,PPO,TPU |

| Product alias:3 in 1 plastic desiccant dryer,PET plastic dryer,PC plastic dryer,PE plastic dryer,resin dryer 3 in 1 Dehumidifying Dryer |

|

| 3 in 1 Dehumidifying Dryer Product introduction |

|

3 in 1 Dehumidifying Dryer parameter

3 in 1 Dehumidifying Dryer 3 in 1 plastic desiccant dryer

Three-in-one protection device

1. Total power supply overcurrent no-fuse circuit breaker;

2, fan overload protection;

3, high temperature trip protection;

4, material suction, material shortage alarm;

5. Overheat protection temperature switch;

working environment

Indoor, dry environment, temperature should not exceed +45℃, humidity should not exceed 80%;Product alias:3 in 1 plastic desiccant dryer,PET plastic dryer,PC plastic dryer,PE plastic dryer,resin dryer |

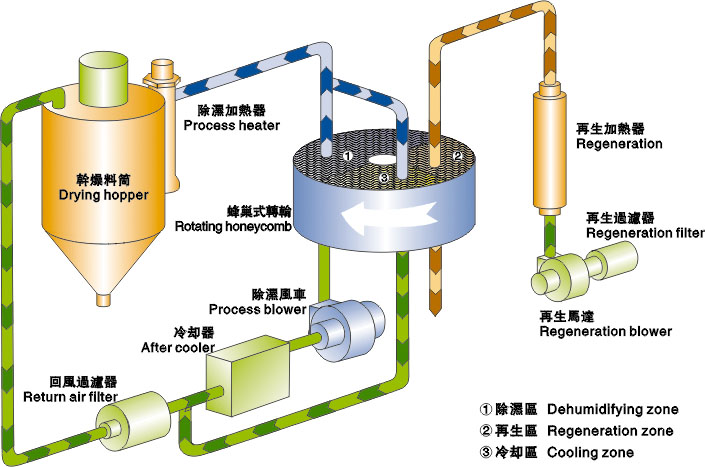

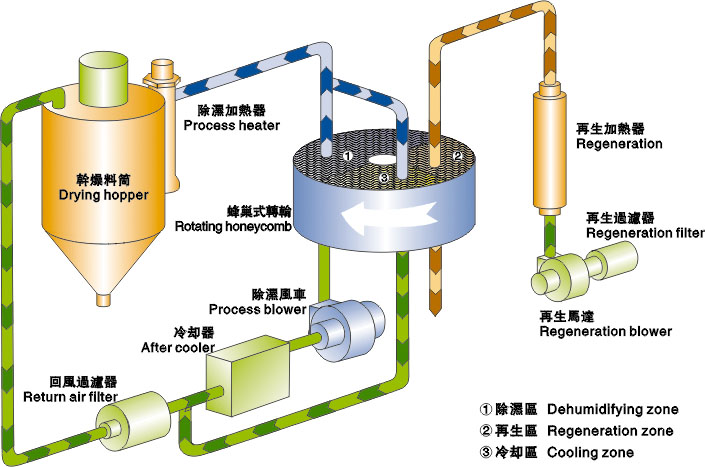

3 in 1 Dehumidifying Dryer Equipment principle

3 in 1 Dehumidifying Dryer 1. The internal circulation of the dehumidifier: through the operation of the compressor → discharge high-temperature and high-pressure gas through the exhaust port → enter the condenser for cooling → become a low-temperature and high-pressure gas → intercept the flow through the capillary tube → become a low-temperature and low-pressure liquid → evaporate and absorb through the evaporator Heat → return to the compressor to become a low temperature and low pressure gas. This cycle is repeated.

2. The external circulation of the dehumidifier: under normal startup → through the operation of the fan → inhalation of moist air from the air inlet → through the evaporator → the evaporator absorbs the moisture in the air on the aluminum sheet → becomes dry air → Pass through the condenser to dissipate heat → blow out from the air outlet.

Product alias:3 in 1 plastic desiccant dryer,PET plastic dryer,PC plastic dryer,PE plastic dryer,resin dryer |

3 in 1 Dehumidifying Dryer application

The three-in-one dehumidification dryer feed combination integrates three functions of dehumidification, drying and feeding in one machine, which is especially suitable for engineering plastic materials with strong moisture absorption such as Plastic ,risin,PET, PA, PC, etc.

1. The dehumidification dryer integrates dehumidification, drying and feeding functions, simple operation, convenient material change, and high work efficiency;

2. The dehumidification dryer is equipped with a honeycomb runner, which can obtain dry air with good stability and low dew point;

3. It can be used in the process application of optical products such as lenses, LCD backlights, optical discs, etc.;

4. It can be equipped with PLC control and LCD touch man-machine interface, centralized and convenient operation, and can control the automatic operation of the whole machine;

5. The closed feeding system can prevent the dried raw materials from re-moisture due to contact with outside air;

6. The dehumidification dryer machine occupies a small area and is easy to move, and the machine can be replaced at will.

3 in 1 plastic desiccant dryer

1. High degree of automation reduces the labor intensity of operators;

2. The honeycomb runner using Japanese ceramic fiber as the base material has good dehumidification effect and stable and reliable performance;

3. It integrates three functions of dehumidification, drying and suction;

4. The feeding system is equipped with a shutoff valve to ensure that there is no residual raw material in the material pipe.

5. PID control of drying temperature and regeneration temperature;

6. PLC touch screen can be added, the operation is simple and clear at a glance;

7. Various complete protection circuits with dehumidification function after shutdown.

8. This series of dehumidification series adopts double cooler structure to ensure lower return air temperature and dew point. 3 in 1 Dehumidifying DryerThis is a device used to dehumidifying plastic resin to achieve drying. For example,

POM,ABS,TPE,PAL,ABS,CAB,EVA(2),EVOH,LM(4),LCP,PA11,PA6.46.6,PAI,PAR,PBT,

PC,PC/ABS,PC/PBT,PE.HDEPE,LDPE black3%,PE.HDEPE.LDPE black40%,PEEK,PE(1),

PEN,PES,PET,PETG,PI,PMMA,POM,PP,PPO,PPS,PS,[GPPS.EPS.HIPS],PSU,PIT,PUR,

PVC,SAN,SB,TPE,TPE,TPO,TPU,

3 in 1 Dehumidifying Dryer,Dehumidifier dryerand other plastic resins must be dehumidified and dried during the production process to improve the quality of the finished product.

Product alias:3 in 1 plastic desiccant dryer,PET plastic dryer,PC plastic dryer,PE plastic dryer,resin dryer |

3 in 1 Dehumidifying Dryer Precautions

3 in 1 Dehumidifying Dryer 3 in 1 plastic desiccant dryer

he desiccant dryer should be cleaned frequently and kept clean. The dehumidifier should be placed in the center of the room. The air inlet and outlet of the refrigerated dryer should not be blocked by obstructions, and the air filter should be cleaned. When the ambient temperature is lower than 15℃, the water droplets attached to the surface of the evaporator will freeze and the effect of the dehumidifier will be weakened. If the ambient temperature exceeds 40℃, the pressure in the system will increase and the compressor will overload. At this time, the overload protector The circuit should be cut off, otherwise the compressor motor will be damaged. So the best temperature range for dehumidifier is 15℃~40℃. If the humidity in the air is below 30%, it will be too dry and uncomfortable. Therefore, a reliable humidity controller will control it to maintain the range of 50% to 60%. When in use, close doors and windows as much as possible to achieve dehumidification in the room. The body of the desiccant dryer must be placed flat, not tilted or turned sideways, to avoid machine failure or abnormal noise.

The water storage in the desiccant dryer is too full. In order to avoid overflowing and contaminating the ground, when you must move the body during operation, please unplug the power cord first, and then pour out the water in the water storage bucket. After moving the dehumidifier, it is best to put it statically for four to six hours before starting to use it. Because the compressor pipeline in the dehumidifier contains cold coal, it must take four to six hours to return the cold coal to its original position after being moved.

Clean the air filter regularly (about once every two weeks) to maintain the dehumidification and dust removal efficiency and life of the machine. Clean the air filter and wash it with water below 40°C; it is better to clean it with detergent. After washing off the dust, rinse it with water, dry it in the shade and put it back into the body. When cleaning the body, wipe it gently with a damp cloth; avoid directly splashing water for cleaning, so as not to damage the electrical insulation. Adhesives on the surface of the body can be cleaned with soap and water. Avoid spraying with gasoline, petroleum spirit, solvent or spray insecticide to avoid peeling paint or discoloration. Do not use thin rods or iron wires to dig out the inside of the machine to avoid malfunction or danger. Please unplug the power cord to maintain the life of the machine when it is out of power, not used for a long time, or when traveling.

Do not use the machine in the following situations

1. There is a damaged line;

2. To prevent electric shock, do not run the machine on a wet floor or after the machine is exposed to rain;

3. If the machine is damaged or disassembled, it should not be overhauled and installed by professional maintenance personnel;

4. During the operation of the machine, at least 1m of surrounding space is required. Please protect this device and flammable materials at least 3m away;

5. Avoid vibration and magnetic influence in the work area;

Product alias:3 in 1 plastic desiccant dryer,PET plastic dryer,PC plastic dryer,PE plastic dryer,resin dryer |

|

|

+8613669807274

+8613669807274

+8613669807274

+8613669807274 wto-btb@wto-btb.com

wto-btb@wto-btb.com Tel: +8613669807274

Tel: +8613669807274 SMS: +8613669807274

SMS: +8613669807274