plastic dryer |

|

|

|

Plastic dryer(Resin dryer) |

Name: Plastic Dryer(Resin dryer) Alias: plastic Dryer, Alias: plastic Dryer,Dehumidifying Dryers, Plastic Resin Dryers, Resin Dehumidifier, Plastic drying equipment. |

Plastic Dryer use:Plastic Dryer Also known as:resin Dryer, Plastic Dehumidifier,Plastic Resin Dryers, Plastic drying equipment, Plastic dryer is a machine that mainly dehumidifies and dries plastic or resin materials. It can dry raw materials that are wet due to packaging, transportation or recycling, and eliminate the problems of bubbles, silver lines, cracks and poor stability, which will affect product quality, thereby reducing waste. The plastic dryer uses screws to push it up, separates and dehydrates, and then automatically loads and unloads. Its unique automatic feeding and discharging functions eliminate the need for manual discharging of traditional centrifuges. Convenient and fast, forming a higher level of automatic assembly line production, greatly saving manpower and improving work efficiency. |

Plastic resin dryers equipment |

Plastic dryer application |

Application of plastic resin parameters of plastic dryer |

|

Plastic |

Dryer |

Density |

Drying time(h) |

Drying temperature |

Atmospheric flow(m3/kg) |

Moulding moisture content(%) |

Initial moisture contnt(%) |

| ABS | √ | 0.55 | 2-3 | 85 | 2 | <0.020 | <0.2 |

| CAB | √ | 0.60 | 2-3 | 70 | 2 | <0.020 | <0.6 |

| EVA(2) | √ | 0.60 | 2-3 | 90-105 | 1.8 | - | - |

| EVOH | √ | 0.60 | 2-3 | 90-105 | 2 | - | - |

| LM(4) | √ | 0.50 | 3 | 600 | 2 | <0.080 | <0.2 |

| LCP | √ | 0.80 | 3-4 | 150 | 2.2 | <0.01 | <0.05 |

| PA11 | √ | 0.60 | 3-5 | 70-80 | 2 | - | 0.6-1.2* |

| PA6.46.6 | √ | 0.60 | 4-6 | 70-80 | 2 | 0.15-0.02* | 0.6-1.2* |

| PAI | √ | 0.85 | 6-8 | 180 | 2 | <0.02 | - |

| PAR | √ | 0.70 | 5-6 | 120 | 2 | <0.02 | - |

| PBT | √ | 0.80 | 3-4 | 130-140 | 2.2 | <0.02 | <0.15 |

| PC | √ | 0.65 | 2-3 | 120 | 2 | <0.02 | <0.3 |

| PC/ABS | √ | 0.65 | 42798 | 100 | 2 | <0.020 | <0.1 |

| PC/PBT | √ | 0.75 | 3-4 | 110 | 2.2 | - | - |

| PE.HDEPE. LDPE black3% |

√ | 0.50 | 1 | 85 | 1.6 | <0.01 | <0.02 |

| PE.HDEPE. LDPE black40% |

√ | 0.70 | 2-3 | 80-90 | 2 | <0.02 | <0.2 |

| PEEK | √ | 0.80 | 3-4 | 150-160 | 2.2 | <0.05 | <00.1 |

| PE(1)(3) | √ | 0.75 | 4-5 | 140-160 | 2.5 | <0.01 | <0.2 |

| PEN(1)(3) | √ | 0.86 | 5-6 | 150-170 | 3 | <0.005 | - |

| PES | √ | 0.80 | 3-4 | 150-180 | 2 | <0.05 | 0.35 |

| PET | √ | 0.84 | 5-6 | 160-180 | 3 | <0.003 | <0.2 |

| PETG | √ | 0.74 | 4-5 | 65 | 3.5 | <0.01 | <0.1 |

| PI | √ | 0.70 | 2-3 | 120 | 2.2 | <0.02 | - |

| PMMA- | √ | 0.65 | 3-4 | 80 | 3 | <0.02 | <0.3 |

| POM | √ | 0.85 | 2-3 | 90-100 | 2 | - | <0.15 |

| PP | √ | 0.50 | 1 | 80-90 | 2 | - | - |

| PPO | √ | 0.55 | 2 | 100-110 | 2 | <0.01 | - |

| PPS | √ | 0.80 | 2-3 | 130-140 | 2 | <0.01 | <0.03 |

| PS [GPPS.EPS.HIPS] |

√ | 0.55 | 1 | 80 | 1.7 | <0.02 | <0.05 |

| PSU | √ | 0.80 | 3-4 | 120-130 | 2 | <0.05 | <0.1 |

| PIT | √ | 0.80 | 5-6 | 130-150 | 3 | <0.05 | <0.2 |

| PUR | √ | 0.75 | 2-3 | 70-90 | 2 | <0.02 | - |

| PVC | √ | 0.85 | 1 | 70-80 | 1.4 | <0.02 | - |

| SAN | √ | 0.55 | 2-3 | 80 | 2 | <0.02 | <0.1 |

| SB | √ | 0.60 | 1-2 | 80 | 2 | <0.02 | - |

| TPE | √ | 0.65 | 2-3 | 110 | 2.2 | <0.05 | <0.3 |

| TPE | √ | 0.65 | 2-3 | 80 | 2.2 | <0.1 | - |

| TPO | √ | 0.55 | 3 | 70-90 | 2 | - | - |

| TPU | √ | 0.75 | 2-3 | 70-100 | 2 | <0.02 | - |

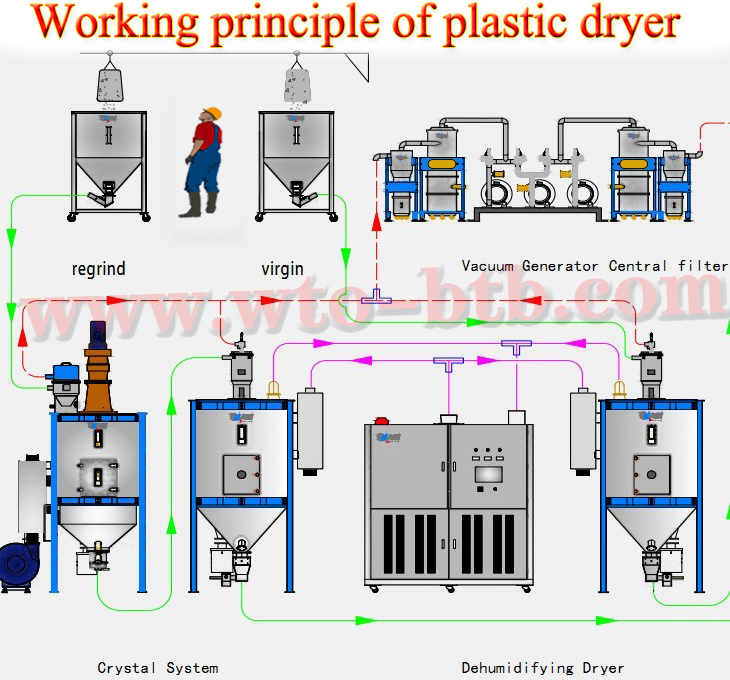

Working principle of plastic dryer |

+8613669807274

+8613669807274