| Resin dryer Details description |

|

| product name:Resin dryer |

| release time:2020-09-16 |

| Numbering: resin dryer,tandard plastic r |

| Brand:wto-btb |

| Price:¥By function |

| weight :By function |

| unit weight:Kg/set |

manufacturer:wto-btb |

| patent:wto-btb |

| Producing country: |

simple description: resin dryer,standard plastic resin dryer:Dehumidify and dry plastic, resin, pet, ppo, pe, pc, tpu, tpe, and other plastics,standard resin dryer,

This is a device used to dehumidifying plastic resin to

achieve drying. For example,POM,ABS,TPE,PAL,ABS,CAB,

EVA(2),EVOH,LM(4),LCP,PA11,PA6.46.6,PAI,PAR,PBT,

PC,PC/ABS,PC/PBT,PE.HDEPE,LDPE black3%,PE.HDEPE.

LDPE black40%,PEEK,PE(1),PEN,PES,PET,PETG,PI,

PMMA,POM,PP,PPO,PPS,PS,[GPPS.EPS.HIPS],PSU,

PIT,PUR,PVC,SAN,SB,TPE,TPE,TPO,TPU,

Dehumidifier dryer and other plastic resins must be

dehumidified and dried during the production process to

improve the quality of the finished product. |

| Product alias:resin dryer,standard plastic resin dryer,plastic resin dryer, resin dryer,Dehumidify and dry plastic, resin, pet, ppo, pe, pc, tpu, tpe, and other plastics |

|

| Resin dryer Product introduction |

|

Resin dryer parameter

resin dryer,Standard Dehumidifying Dryer

1. This series adopts the microcomputer P. I. D. temperature control system to control the temperature accurately;

2. Adopting Nigas brand full molecular sieve honeycomb dehumidification runner imported from Japan, the dehumidification effect is better and more stable;

3. Enlarged and equipped with detachable cooler, easy maintenance and lower return air temperature;

4. resin dryer,High-density return air filter to ensure that the honeycomb runner is not polluted by raw material dust;

5. Double-layer insulation and downward blowing stainless steel dryer;

6. The feeding system is equipped with an evacuation shutoff valve (quickly disassembled) to ensure that there is no residual material in the pipe;

7. Hot material conveying can be equipped with a closed conveying device of hot air loop, which can effectively avoid raw material pollution and moisture resurgence;

8. Optional optical grade hopper dryer to suit the production of optical grade and food grade products;

9. The filter is designed with a transparent window, which can observe the use of the filter and clean or replace it regularly;

10. The snap-on sealing plate design makes later maintenance and repair more convenient;

11. The dew point of the air after dehumidification can be as low as -40°C.

| Model |

Capacity (KG) |

HeatingPower

(KW) |

Blower

(W) |

Power

(V) |

Dimensions

(HxWxD,MM) |

Approx.Net Weight

(KG) |

| HGB-6 |

6 |

1.5 |

150 |

1φ 220V |

490x490x785 |

25 |

| HGB-12 |

12 |

2 |

160 |

1φ 220V |

540x435x850 |

35 |

| HGB-25 |

25 |

3 |

150 |

1φ 220V |

605x560x1240 |

50 |

| HGB-50 |

50 |

3.9 |

160 |

3φ 380V |

706x594x1410 |

75 |

| HGB-75 |

75 |

4.2 |

240 |

3φ 380V |

751x649x1520 |

105 |

| HGB-100 |

100 |

6.2 |

240 |

3φ 380V |

817x581x1670 |

125 |

| HGB-150 |

150 |

7 |

240 |

3φ 380V |

868x710x1800 |

160 |

| HGB-200 |

200 |

11 |

300 |

3φ 380V |

995x830x1930 |

210 |

| HGB-300 |

300 |

18 |

320 |

3φ 380V |

1160x975x2280 |

330 |

| HGB-400 |

400 |

20 |

360 |

3φ 380V |

1220x990x2330 |

365 |

| HGB-500 |

500 |

22 |

750 |

3φ 380V |

1150x1045x2430 |

385 |

| HGB-600 |

600 |

24 |

750 |

3φ 380V |

1210x1070x2540 |

400 |

| HGB-800 |

800 |

30 |

1500 |

3φ 380V |

1390x1120x2730 |

600 |

| HGB-1000 |

1000 |

36 |

1500 |

3φ 380V |

1525x1425x3670 |

650 |

| HGB-1200 |

1200 |

36 |

1500 |

3φ 380V |

1600x1510x3722 |

835 |

| HGB-1500 |

1500 |

40 |

2200 |

3φ 380V |

1730x1680x3880 |

900 |

| HGB-1800 |

1800 |

45 |

2200 |

3φ 380V |

1835x1680x4060 |

1005 |

| HGB-2000 |

2000 |

45 |

2200 |

3φ 380V |

1870x1710x4415 |

1130 |

| HGB-3000 |

3000 |

50 |

3700 |

3φ 380V |

2080x1920x4520 |

1650 |

| HGB-3500 |

3500 |

50 |

3700 |

3φ 380V |

2141x1976x4863 |

2120 |

| HGB-4000 |

4000 |

60 |

3700 |

3φ 380V |

2192x2040x4936 |

2870 |

| HGB-5000 |

5000 |

60 |

5500 |

3φ 380V |

2355x2160x5120 |

3510 |

Product alias:resin dryer,standard plastic resin dryer,plastic resin dryer, resin dryer,Dehumidify and dry plastic, resin, pet, ppo, pe, pc, tpu, tpe, and other plastics,Resin dryer |

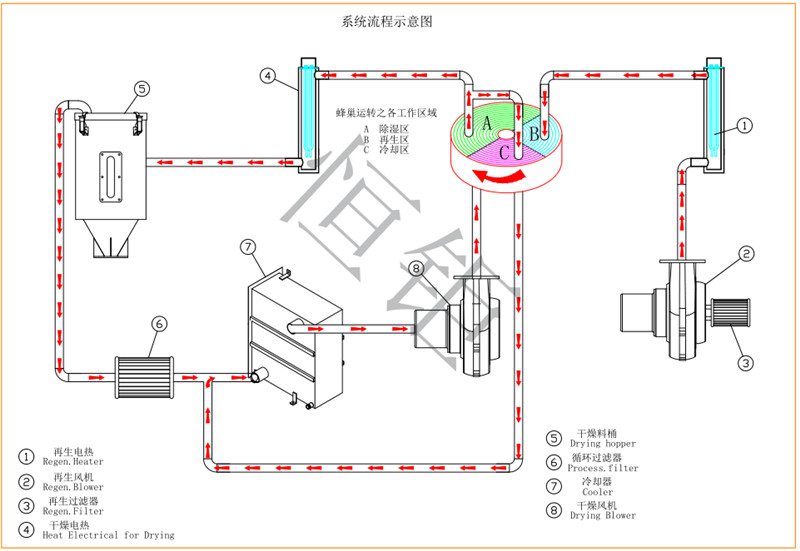

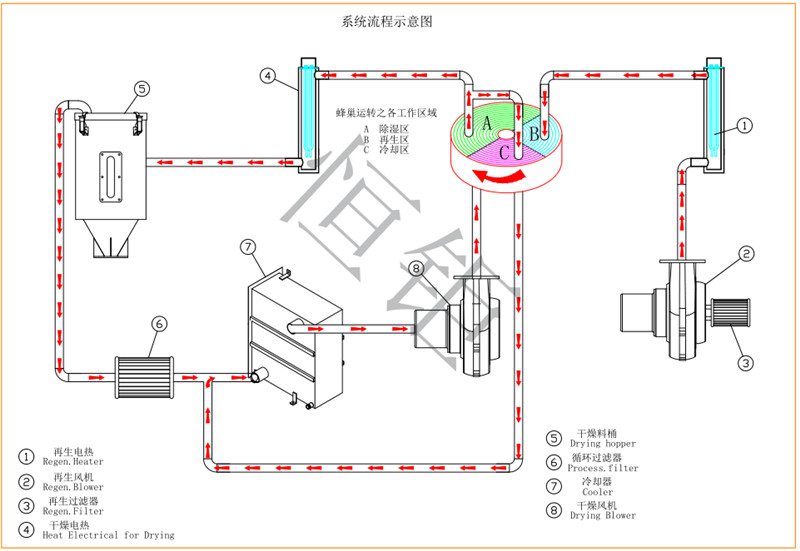

Resin dryer Equipment principle

resin dryer,Standard Dehumidifying Dryer

resin dryer,The standard plastic resin dryer is the most effective and economical model for drying plastic raw materials. It can dry raw materials that are wet due to packaging, transportation or recycling.

The hopper is made of stainless steel, with the functions of "hot air blowing down" and "cyclone exhaust" as well as a double-layer insulation barrel, which is especially suitable for drying engineering plastic materials with a dehumidifier.

The air blown by the drying fan becomes high-temperature dry air after drying and electric heating. Through the unique design of the lower blowing pipe, the hot air is evenly dispersed in the insulation barrel to dry the raw materials; the hot air recovery device is optional, and the air blown out is filtered and then dried The wind blows out, forming a closed loop.

Drying and dehumidifying part: The hot and humid air returned from the drying barrel is cooled and blown into the honeycomb runner. The moisture in the air is adsorbed by the runner and then desorbed by the regeneration heating air. The two airflows act on the runner at the same time, and with the rotation of the runner, the moisture in the air is continuously adsorbed and then desorbed by the regeneration air to be discharged, forming a stable low dew point air, which is heated to the plastic The drying temperature is blown into the drying barrel to form a closed cycle to dry the raw materials.

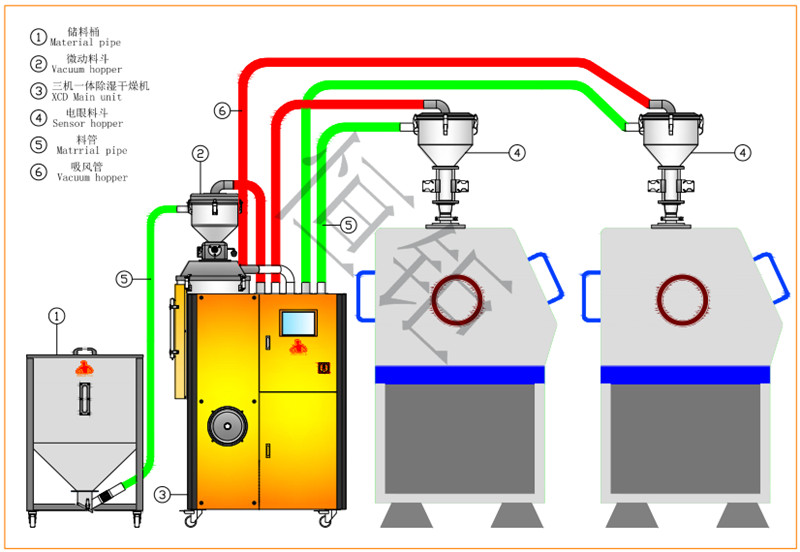

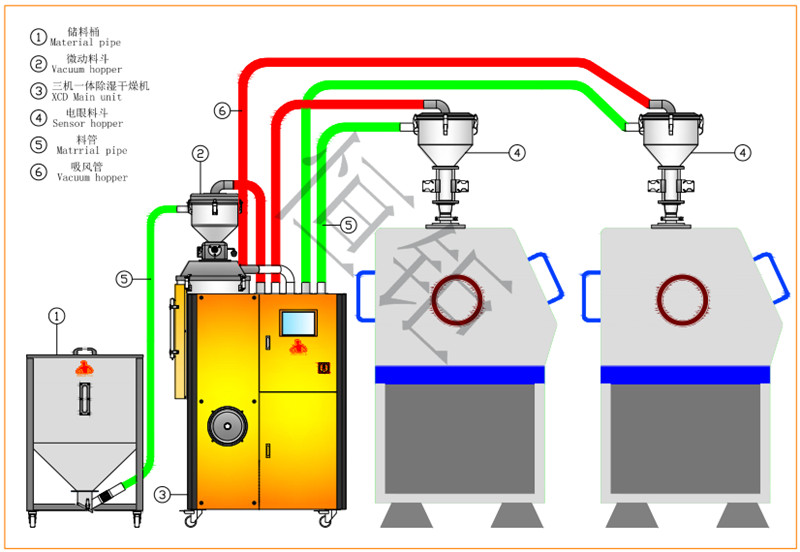

Suction part: Suction material is sucked into the dry bucket from the storage bucket or other storage container. When the reed switch of the vacuum hopper detects that there is no material, the suction motor runs to generate vacuum in the vacuum hopper. The raw materials in the bucket are sucked into the vacuum hopper due to the air pressure difference. When the suction time is completed, the suction motor stops running, and the raw materials fall into the drying bucket due to their own weight. The dried raw materials are pumped from the drying barrel to the photoelectric hopper or micro-motion hopper installed in the plastic molding machine. Resin dryer It adopts double condenser structure to ensure lower return air temperature and dew point.

1. Resin dryer Adopt P.I.D temperature control system, which has regeneration temperature setting and actual temperature display screen.

2. Adjustable rotating speed control of honeycomb wheel.

3. The honeycomb can reach a dew point of -40°C, and can reach a dew point of -50°C or even lower when the configuration is enhanced.

4. Optional PLC control with LCD touch man-machine interface.

5. Dew point meter that can monitor the dehumidification effect of the machine at any time is optional.

6. The machine occupies a small area and is easy to move, and the machine can be replaced at will.

Product alias:resin dryer,standard plastic resin dryer,plastic resin dryer, resin dryer,Dehumidify and dry plastic, resin, pet, ppo, pe, pc, tpu, tpe, and other plastics |

Resin dryer application

resin dryer,Standard Dehumidifying Dryer

Plastic resin dryers can be widely used in civil air defense engineering, tobacco factories, pharmaceutical factories, scientific research, industry, medical and health, instrumentation, commodity storage, underground engineering, and computer rooms, archives, warehouses and other high humidity places to prevent instruments, meters, Computers, telecommunications equipment, medicines, materials, etc. are damaged by moisture, rust, and mildew. It can work normally when the relative humidity of the environment is within the range of 35-95% and the ambient temperature is 5-38 degrees Celsius. It is mainly used in basements, archives, precision instrument rooms, workshops and warehouses of pharmaceutical factories, electronic factories, industry, storage, etc., which require high relative air humidity. It can improve product quality, humidity hazards, and mold hazards. Everywhere in daily life. Therefore, it is necessary to add dryers to the above-mentioned environment.

1. Foundry industry:

In this process, the wax mold is repeatedly immersed in the clay. These outer layers form the mold. When the wax is melted, the molten metal can be poured into it. Dry air (very low vapor pressure) is better than others. The heating source is more commonly used to dry the clay layer, because the dry air will not deform the wax mold. The use of a hygroscopic dehumidifier can stabilize the operating cost of foundries in the foundry industry and increase the production volume without slowing down the production pace in the wet months, and the process drying time can be shortened by 50%.

2. Dehumidification and drying of plastic raw material resin:

All plastic raw material resins have a certain degree of hygroscopicity. When the plastic raw material particles are extruded, the moisture is heated and evaporated by the plastic raw material dehumidifier. These vapors will cause cracks in the structure and appearance of the plastic material. The desiccant dryer can reduce the humidity in the plastic raw materials and improve the quality of the finished product.

Resin dryer;This is a device used to dehumidifying plastic resin to achieve drying. For example,

POM,ABS,TPE,PAL,ABS,CAB,EVA(2),EVOH,LM(4),LCP,PA11,PA6.46.6,PAI,PAR,PBT,

PC,PC/ABS,PC/PBT,PE.HDEPE,LDPE black3%,PE.HDEPE.LDPE black40%,PEEK,PE(1),

PEN,PES,PET,PETG,PI,PMMA,POM,PP,PPO,PPS,PS,[GPPS.EPS.HIPS],PSU,PIT,PUR,

PVC,SAN,SB,TPE,TPE,TPO,TPU,

Dehumidifier dryerand other plastic resins must be dehumidified and dried during the production process to improve the quality of the finished product.

Product alias:resin dryer,standard plastic resin dryer,plastic resin dryer, resin dryer,Dehumidify and dry plastic, resin, pet, ppo, pe, pc, tpu, tpe, and other plastics,Resin dryer |

Resin dryer Precautions

resin dryer,Standard Dehumidifying Dryer

The water storage capacity of the standard plastic resin dryer is too full. To avoid overflowing and contaminating the ground, when you must move the body during operation, please unplug the power cord first, and then pour out the water in the water storage bucket. After moving the dehumidifier, it is best to put it statically for four to six hours before starting to use it. Because the compressor pipeline in the dehumidifier contains cold coal, it must take four to six hours to return the cold coal to its original position after being moved. Clean the air filter regularly (about once every two weeks) to maintain the dehumidification and dust removal efficiency and life of the machine. Clean the air filter and wash it with water below 40°C; it is better to clean it with detergent. After washing off the dust, rinse it with water, dry it in the shade and put it back into the body.

When cleaning the body, wipe it gently with a damp cloth; avoid directly splashing water for cleaning, so as not to damage the electrical insulation. Adhesives on the surface of the body can be cleaned with soap and water. Avoid spraying with gasoline, petroleum spirit, solvent or spray insecticide to avoid peeling paint or discoloration. Do not use thin rods or iron wires to dig out the inside of the machine to avoid malfunction or danger. Please unplug the power cord to maintain the life of the machine when it is out of power, not used for a long time, or when traveling.

In fact, it is also very useful to connect to our lives. The standard plastic resin dryer consists of a compressor, a fan, and other components. The fan draws air in, and the heat exchanger condenses the moisture into droplets and then discharges it.

Resin dryer Maintenance:

1. Resin dryerCheck the parts regularly, 1-2 times a month. The inspection items are whether the worm, bearing, shaft seal and other movable parts are flexible in rotation and wear. Any defects should be repaired in time for normal use.

2.Resin dryer Electrical control parts should be kept clean and sensitive, and faults should be repaired in time.

3.Resin dryer When one use is completed or work is stopped, the remaining materials should be taken out of the plastic drying and mixing machine, and the remaining powder in each part of the machine should be cleaned. If it is out of service for a long time, the machine must be wiped clean and covered with a tarp cloth.

4.Resin dryer When assembling and disassembling the mixing paddle of the plastic drying color mixing machine, it should be disassembled, steadily installed, and handled gently to avoid deformation and damage.

Correct operation for Resin dryer:![Resin dryer,resin dryer,standard plastic resin dryer,plastic resin dryer, resin dryer,Dehumidify and dry plastic, resin, pet, ppo, pe, pc, tpu, tpe, and other plastics,POM,ABS,TPE,PAL,ABS,CAB,EVA(2),EVOH,LM(4),LCP,PA11,PA6.46.6,PAI,PAR,PBT,PC,PC/ABS,PC/PBT,PE.HDEPE,LDPE black3%,PE.HDEPE.LDPE black40%,PEEK,PE(1),PEN,PES,PET,PETG,PI,PMMA,POM,PP,PPO,PPS,PS,[GPPS.EPS.HIPS],PSU,PIT,PUR,PVC,SAN,SB,TPE,TPE,TPO,TPU,Resin dryer](/d/file/p/2020/09-16/fb18d41f7a92b1cf7931c70b5fba973e.jpg) 1. Before starting up, check the power distribution of all equipment and pipelines before work. If there are hidden dangers, remove them and deal with them in time.

2. Clean the air inlet filter of the heater.

3. When the temperature of the imported heat transfer oil of the main engine rises to 100-120℃, the induced air can be started.

4. The inlet temperature of the cloth bag can reach 70℃ or higher, which can be opened for stirring, stirring, and the number of rotations is appropriate.

5. Air pressure: main machine inlet 6-10Mpa, cloth bag inlet, main machine outlet 20-26Mpa, cloth bag outlet 36-40Mpa.

6. Unloading will start within 15 minutes when the machine is turned on and the unloading cannot be stopped for any reason, until the material in the bag box is unloaded after the machine stops.

7. Each shift must have a special person to watch the instrument on the panel, and if there is an abnormality, and find it out in time, the watcher can not leave without authorization until the machine stops.

8. The feeding personnel should carefully observe the material during feeding to avoid foreign matter in the material and cause accidents.

9. In normal work, the temperature of the heat transfer oil inlet cannot exceed 250°C, otherwise it will be opened and closed immediately to cool down.

10. When you hear noise in the host during work, stop it immediately, open the side door of the host, cool down and use a magnetic stick or touch it to clean out the foreign objects.

11. When the power is cut off during work, immediately close the thermal oil valve, open and close, and open the side door of the main engine to cool down.

12.Resin dryer When the power is cut, the cloth bag should be cleaned first. When the induced air is turned on, open the side door of the main unit to observe whether there is sparks. If necessary, spray with water (mist).

13. If there is a sudden change in the radiator oil bag pipeline (severe oil leakage, fire, etc.), the main oil guide valve should be closed immediately, and on-site fire fighting should be carried out immediately, and the boiler should be notified to cool down.

14. If sparks and explosions are found on the main engine and the bag box, immediately stop the induced air, open the closed valve, and close the valve of the main oil pipeline.

15. When you find sparks in the bag, take the time to unwind the material that is on fire, flush the bag with water, and control the amount of water to prevent the bag from being damaged even if the water level is too high.

16. Resin dryer Operators must keep a clear head when they are on the job, and keep patrolling and checking and not leaving the job without permission.

1. Before starting up, check the power distribution of all equipment and pipelines before work. If there are hidden dangers, remove them and deal with them in time.

2. Clean the air inlet filter of the heater.

3. When the temperature of the imported heat transfer oil of the main engine rises to 100-120℃, the induced air can be started.

4. The inlet temperature of the cloth bag can reach 70℃ or higher, which can be opened for stirring, stirring, and the number of rotations is appropriate.

5. Air pressure: main machine inlet 6-10Mpa, cloth bag inlet, main machine outlet 20-26Mpa, cloth bag outlet 36-40Mpa.

6. Unloading will start within 15 minutes when the machine is turned on and the unloading cannot be stopped for any reason, until the material in the bag box is unloaded after the machine stops.

7. Each shift must have a special person to watch the instrument on the panel, and if there is an abnormality, and find it out in time, the watcher can not leave without authorization until the machine stops.

8. The feeding personnel should carefully observe the material during feeding to avoid foreign matter in the material and cause accidents.

9. In normal work, the temperature of the heat transfer oil inlet cannot exceed 250°C, otherwise it will be opened and closed immediately to cool down.

10. When you hear noise in the host during work, stop it immediately, open the side door of the host, cool down and use a magnetic stick or touch it to clean out the foreign objects.

11. When the power is cut off during work, immediately close the thermal oil valve, open and close, and open the side door of the main engine to cool down.

12.Resin dryer When the power is cut, the cloth bag should be cleaned first. When the induced air is turned on, open the side door of the main unit to observe whether there is sparks. If necessary, spray with water (mist).

13. If there is a sudden change in the radiator oil bag pipeline (severe oil leakage, fire, etc.), the main oil guide valve should be closed immediately, and on-site fire fighting should be carried out immediately, and the boiler should be notified to cool down.

14. If sparks and explosions are found on the main engine and the bag box, immediately stop the induced air, open the closed valve, and close the valve of the main oil pipeline.

15. When you find sparks in the bag, take the time to unwind the material that is on fire, flush the bag with water, and control the amount of water to prevent the bag from being damaged even if the water level is too high.

16. Resin dryer Operators must keep a clear head when they are on the job, and keep patrolling and checking and not leaving the job without permission.

Product alias:resin dryer,standard plastic resin dryer,plastic resin dryer, resin dryer,Dehumidify and dry plastic, resin, pet, ppo, pe, pc, tpu, tpe, and other plastics,Resin dryer |

|

|

+8613669807274

+8613669807274

+8613669807274

+8613669807274 wto-btb@wto-btb.com

wto-btb@wto-btb.com Tel: +8613669807274

Tel: +8613669807274 SMS: +8613669807274

SMS: +8613669807274