| Honeycomb Dehumidifying dryer Details description |

|

| product name:Honeycomb Dehumidifying dryer |

| release time:2020-09-12 |

| Numbering:Honeycomb dehumidifier dryer-0 |

| Brand:wto-btb |

| Price:¥By function |

| weight :By function |

| unit weight:Kg/set |

manufacturer:wto-btb |

| patent:wto-btb |

| Producing country:china |

simple description:Plastic dehumidifiers are used to dehumidify plastics or resins to achieve drying and improve product quality, such as: PC, PET, PE, TPU, PPO and other materials,

This is a device used to dehumidifying plastic resin to

achieve drying. For example,POM,ABS,TPE,PAL,ABS,CAB,

EVA(2),EVOH,LM(4),LCP,PA11,PA6.46.6,PAI,PAR,PBT,

PC,PC/ABS,PC/PBT,PE.HDEPE,LDPE black3%,PE.HDEPE.

LDPE black40%,PEEK,PE(1),PEN,PES,PET,PETG,PI,

PMMA,POM,PP,PPO,PPS,PS,[GPPS.EPS.HIPS],PSU,

PIT,PUR,PVC,SAN,SB,TPE,TPE,TPO,TPU,

Dehumidifier dryer and other plastic resins must be

dehumidified and dried during the production process to

improve the quality of the finished product. |

| Product alias:Plastic dehumidifier,Plastic dryer,Plastic dehumidifier dryer,Honeycomb Dehumidifier,Resin dryer, resin dehumidifier, Honeycomb Dehumidifying dryer |

|

| Honeycomb Dehumidifying dryer Product introduction |

|

Honeycomb Dehumidifying dryer parameter

There are many models of plastic dehumidifiers, and different parameters are set according to different products. The following is a general parameter table:

| Model |

Drying Air Volume |

Drying Blower Power |

Regeration Fan |

Renewable electric |

Cooling nozzle |

out/in wind dia. |

Dimensions |

Approx.Net Weight |

| |

(m^3/hr) |

(KW) |

(KW) |

(KW) |

(inch) |

(inch) |

(cm)LxWxh |

(KG) |

| HF-80 |

80 |

0.75 |

0.2 |

3.8 |

3/4" |

2 |

82×55×128 |

145 |

| HF-120 |

120 |

1.1 |

0.375 |

3.8 |

3/4" |

2 |

82×55×128 |

170 |

| HF-150 |

150 |

1.5 |

0.375 |

5.4 |

3/4" |

2 |

82×55×128 |

170 |

| HF-200 |

200 |

2.2 |

0.375 |

5.4 |

3/4" |

2.5 |

105×66×153 |

265 |

| HF-300 |

300 |

3.8 |

0.75 |

7.2 |

3/4" |

3 |

126×70×170 |

285 |

| HF-400 |

400 |

5.5 |

0.75 |

7.2 |

3/4" |

3 |

126×70×170 |

330 |

| HF-500 |

500 |

7.5 |

1.5 |

10 |

3/4" |

4 |

130×90×180 |

350 |

| HF-700 |

700 |

2.2 |

2.2 |

12 |

3/4" |

4 |

130×90×180 |

480 |

| HF-1000 |

1000 |

3.7 |

2.2 |

12 |

3/4" |

5 |

168×125×190 |

700 |

| HF-1200 |

1200 |

3.7 |

2.2 |

12 |

3/4" |

6 |

168×125×190 |

860 |

| HF-1500 |

1500 |

5.5 |

2.2 |

15 |

3/4" |

6 |

168×125×190 |

1100 |

| HF-2000 |

2000 |

5.5 |

2.2 |

15 |

11/4" |

8 |

210×141×196 |

1300 |

| HF-2000 |

2000 |

3.7x2 |

2.2*2 |

12*2 |

11/4" |

8 |

210×141×196 |

1400 |

| HF-3000 |

3000 |

5.5x2 |

2.2*2 |

15*2 |

11/4" |

8 |

224×220×210 |

1600 |

| HF-4000 |

4000 |

7.5x2 |

2.2*2 |

20*2 |

11/4" |

12 |

224×220×210 |

2200 |

| Model |

Capacity (KG) |

HeatingPower

(KW) |

Blower

(W) |

Power

(V) |

Dimensions

(HxWxD,MM) |

Approx.Net Weight

(KG) |

| HGB-6 |

6 |

1.5 |

150 |

1φ 220V |

490x490x785 |

25 |

| HGB-12 |

12 |

2 |

160 |

1φ 220V |

540x435x850 |

35 |

| HGB-25 |

25 |

3 |

150 |

1φ 220V |

605x560x1240 |

50 |

| HGB-50 |

50 |

3.9 |

160 |

3φ 380V |

706x594x1410 |

75 |

| HGB-75 |

75 |

4.2 |

240 |

3φ 380V |

751x649x1520 |

105 |

| HGB-100 |

100 |

6.2 |

240 |

3φ 380V |

817x581x1670 |

125 |

| HGB-150 |

150 |

7 |

240 |

3φ 380V |

868x710x1800 |

160 |

| HGB-200 |

200 |

11 |

300 |

3φ 380V |

995x830x1930 |

210 |

| HGB-300 |

300 |

18 |

320 |

3φ 380V |

1160x975x2280 |

330 |

| HGB-400 |

400 |

20 |

360 |

3φ 380V |

1220x990x2330 |

365 |

| HGB-500 |

500 |

22 |

750 |

3φ 380V |

1150x1045x2430 |

385 |

| HGB-600 |

600 |

24 |

750 |

3φ 380V |

1210x1070x2540 |

400 |

| HGB-800 |

800 |

30 |

1500 |

3φ 380V |

1390x1120x2730 |

600 |

| HGB-1000 |

1000 |

36 |

1500 |

3φ 380V |

1525x1425x3670 |

650 |

| HGB-1200 |

1200 |

36 |

1500 |

3φ 380V |

1600x1510x3722 |

835 |

| HGB-1500 |

1500 |

40 |

2200 |

3φ 380V |

1730x1680x3880 |

900 |

| HGB-1800 |

1800 |

45 |

2200 |

3φ 380V |

1835x1680x4060 |

1005 |

| HGB-2000 |

2000 |

45 |

2200 |

3φ 380V |

1870x1710x4415 |

1130 |

| HGB-3000 |

3000 |

50 |

3700 |

3φ 380V |

2080x1920x4520 |

1650 |

| HGB-3500 |

3500 |

50 |

3700 |

3φ 380V |

2141x1976x4863 |

2120 |

| HGB-4000 |

4000 |

60 |

3700 |

3φ 380V |

2192x2040x4936 |

2870 |

| HGB-5000 |

5000 |

60 |

5500 |

3φ 380V |

2355x2160x5120 |

3510 |

Product alias:Plastic dehumidifier,Plastic dryer,Plastic dehumidifier dryer,Honeycomb Dehumidifier,Resin dryer, resin dehumidifier, Honeycomb Dehumidifying dryer,Honeycomb Dehumidifying dryer |

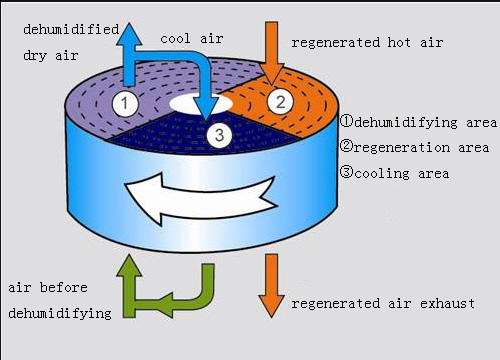

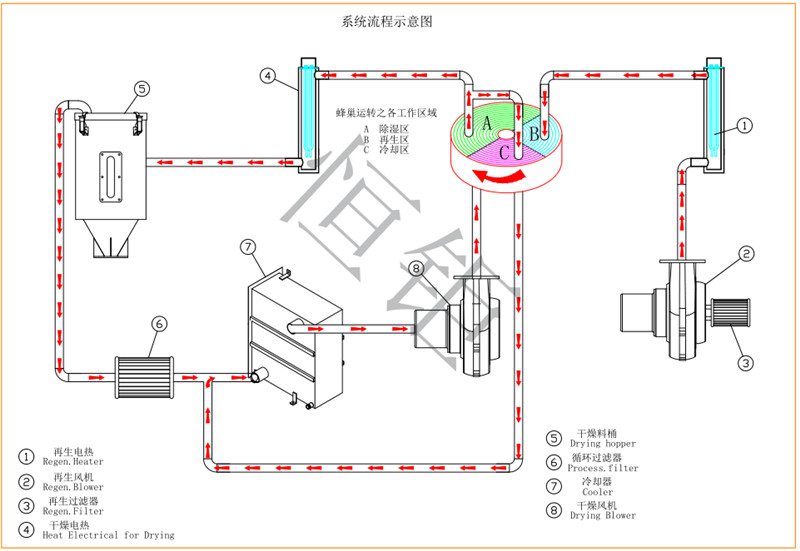

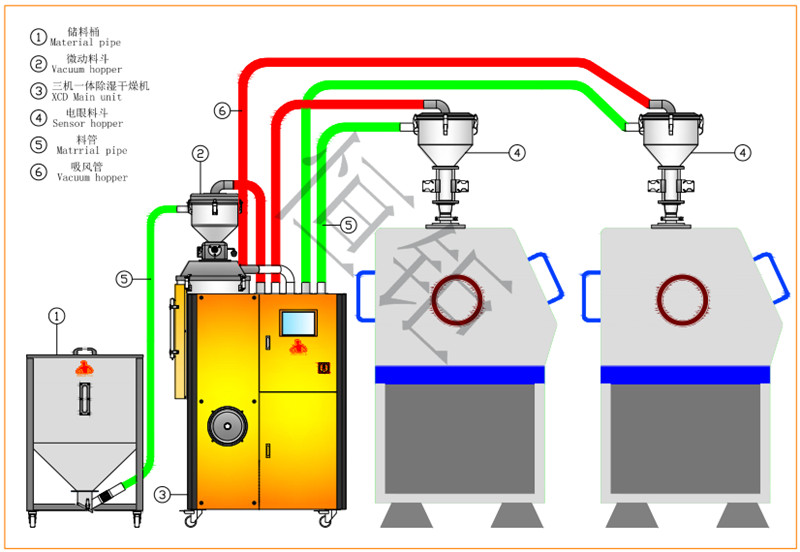

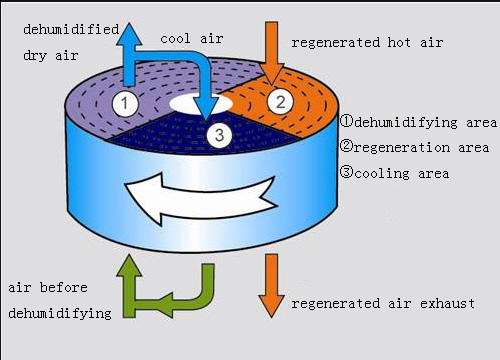

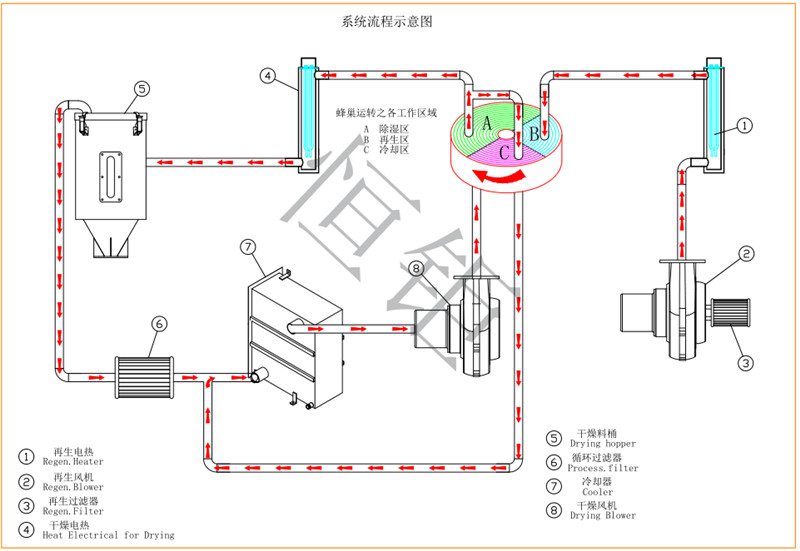

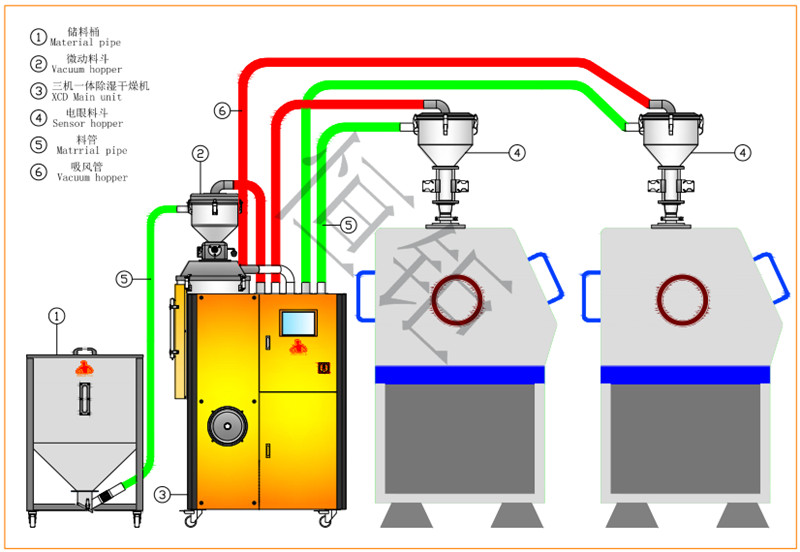

Honeycomb Dehumidifying dryer Equipment principle

Honeycomb dehumidifier dryer

1. The unit has high air pressure and uses top-out air to supply air.

2. The control part adopts advanced control components, which has the characteristics of high control precision and convenient adjustment.

3. The use of industrial fans has a long air supply distance, which is conducive to uniform temperature and humidity distribution in the room

4. The compressor is placed in the indoor unit, the whole system is more reliable, and it is equipped with high and low pressure gauges, which is convenient for equipment maintenance and repair

5. The original scroll type fully enclosed compressor is adopted, which is highly efficient and energy-saving

6. Taking into account the complex changes of the working environment, the system is equipped with complete automatic protection functions, such as high and low pressure protection, and fluorine deficiency related protection.

7. Control system:

Electronic microcomputer temperature and humidity controller: digital temperature and humidity display, user parameter setting, easy operation and precise control; supporting high-precision temperature and humidity sensor, can automatically realize temperature and humidity control.

1. This machine adopts P.I.D. temperature control system, which can accurately control the regeneration temperature;

2. This series of dehumidification system adopts double cooler structure to ensure lower return air temperature and dew point;

3. Dry electric heating and temperature control meter are optional, and the drying barrel can be used to dehumidify and dry raw materials;

4. A return air filter is installed inside to ensure that the honeycomb wheel is not polluted by raw material dust.

TD-H series honeycomb rotary dehumidifier is mainly used for high-efficiency dehumidification of engineering plastics with strong hygroscopicity. The honeycomb wheel used by our company can reach -40℃ under ideal conditions; the whole series adopt PID temperature control system as standard equipment, and also provide PLC control with LCD control touch man-machine interface for purchase, providing real-time The dew point meter that monitors the dehumidification effect of the machine is optional. There are 14 models in this series, and the maximum drying air volume can reach 4000m3/hr. Honeycomb Dehumidifying dryer It adopts double condenser structure to ensure lower return air temperature and dew point.

1. Honeycomb Dehumidifying dryer Adopt P.I.D temperature control system, which has regeneration temperature setting and actual temperature display screen.

2. Adjustable rotating speed control of honeycomb wheel.

3. The honeycomb can reach a dew point of -40°C, and can reach a dew point of -50°C or even lower when the configuration is enhanced.

4. Optional PLC control with LCD touch man-machine interface.

5. Dew point meter that can monitor the dehumidification effect of the machine at any time is optional.

6. The machine occupies a small area and is easy to move, and the machine can be replaced at will.

Product alias:Plastic dehumidifier,Plastic dryer,Plastic dehumidifier dryer,Honeycomb Dehumidifier,Resin dryer, resin dehumidifier, Honeycomb Dehumidifying dryer |

Honeycomb Dehumidifying dryer application

Plastic dehumidifiers are mainly suitable for underground engineering, national defense engineering, archives, libraries, factory workshops, warehouses, computer rooms, and environments that require temperature and humidity. The temperature-adjustable dehumidifier can automatically adjust temperature, cool down and dehumidify. The temperature-adjustable dehumidifier integrates dehumidification and refrigeration functions with adjustable cooling capacity, which is especially suitable for dehumidifying places in high temperature and high humidity environments with large thermal load changes. The unit automatically runs in the cold air dehumidification mode, and the heat generated by the unit is dissipated into the outdoor atmosphere through the outdoor unit; in the low temperature, cold and humid environment, the unit automatically runs in dehumidification conditions. The cooling dehumidifier has a refrigeration function while reducing humidity, but the refrigeration function is not adjustable. It is suitable for dehumidification occasions with large heat load and no relative humidity requirements.

The following are the corresponding parameters of general plastic or resin materials:Honeycomb dehumidifier dryer

|

Plastic material |

Dryer |

Density

(kg/dm3) |

Drying time(h) |

Drying temperature

(℃) |

Atmospheric flow

(m3/kg) |

Moulding moisture content |

Initial moisture contnt(%) |

|

ABS |

√ |

0.55 |

2-3 |

85 |

2 |

<0.020 |

< 0.2 |

|

CAB |

√ |

0.60 |

2-3 |

70 |

2 |

<0.020 |

< 0.6 |

|

EVA(2) |

√ |

0.60 |

2-3 |

90-105 |

1.8 |

- |

- |

|

EVOH |

√ |

0.60 |

2-3 |

90-105 |

2 |

- |

- |

|

LM(4) |

√ |

0.50 |

3 |

600 |

2 |

<0.080 |

<0.2 |

|

LCP |

√ |

0.80 |

3-4 |

150 |

2.2 |

< 0.01 |

<0.05 |

|

PA11 |

√ |

0.60 |

3-5 |

70-80 |

2 |

- |

0.6-1.2* |

|

PA6.46.6 |

√ |

0.60 |

4-6 |

70-80 |

2 |

0.15-0.02* |

0.6-1.2* |

|

PAI |

√ |

0.85 |

6-8 |

180 |

2 |

<0.02 |

- |

|

PAR |

√ |

0.70 |

5-6 |

120 |

2 |

<0.02 |

- |

|

PBT |

√ |

0.80 |

3-4 |

130-140 |

2.2 |

<0.02 |

< 0.15 |

|

PC |

√ |

0.65 |

2-3 |

120 |

2 |

< 0.02 |

< 0.3 |

|

PC/ABS |

√ |

0.65 |

42798 |

100 |

2 |

< 0.020 |

<0.1 |

|

PC/PBT |

√ |

0.75 |

3-4 |

110 |

2.2 |

- |

- |

|

PE.HDEPE.LDPE black3% |

√ |

0.50 |

1 |

85 |

1.6 |

<0.01 |

<0.02 |

|

PE.HDEPE.LDPE black40% |

√ |

0.70 |

2-3 |

80-90 |

2 |

<0.02 |

<0.2 |

|

PEEK |

√ |

0.80 |

3-4 |

150-160 |

2.2 |

<0.05 |

<00.1 |

|

PE(1)(3) |

√ |

0.75 |

4-5 |

140-160 |

2.5 |

<0.01 |

<0.2 |

|

PEN(1)(3) |

√ |

0.86 |

5-6 |

150-170 |

3 |

<0.005 |

- |

|

PES |

√ |

0.80 |

3-4 |

150-180 |

2 |

<0.05 |

0.35 |

|

PET |

√ |

0.84 |

5-6 |

160-180 |

3 |

<0.003 |

< 0.2 |

|

PETG |

√ |

0.74 |

4-5 |

65 |

3.5 |

<0.01 |

<0.1 |

|

PI |

√ |

0.70 |

2-3 |

120 |

2.2 |

<0.02 |

- |

|

PMMA- |

√ |

0.65 |

3-4 |

80 |

3 |

< 0.02 |

<0.3 |

|

POM |

√ |

0.85 |

2-3 |

90-100 |

2 |

- |

<0.15 |

|

PP |

√ |

0.50 |

1 |

80-90 |

2 |

- |

- |

|

PPO |

√ |

0.55 |

2 |

100-110 |

2 |

<0.01 |

- |

|

PPS |

√ |

0.80 |

2-3 |

130-140 |

2 |

<0.01 |

<0.03 |

|

PS[GPPS.EPS.HIPS] |

√ |

0.55 |

1 |

80 |

1.7 |

<0.02 |

<0.05 |

|

PSU |

√ |

0.80 |

3-4 |

120-130 |

2 |

<0.05 |

<0.1 |

|

PIT |

√ |

0.80 |

5-6 |

130-150 |

3 |

<0.05 |

<0.2 |

|

PUR |

√ |

0.75 |

2-3 |

70-90 |

2 |

<0.02 |

- |

|

PVC |

√ |

0.85 |

1 |

70-80 |

1.4 |

<0.02 |

- |

|

SAN |

√ |

0.55 |

2-3 |

80 |

2 |

<0.02 |

<0.1 |

|

SB |

√ |

0.60 |

1-2 |

80 |

2 |

<0.02 |

- |

|

TPE |

√ |

0.65 |

2-3 |

110 |

2.2 |

<0.05 |

<0.3 |

|

TPE |

√ |

0.65 |

2-3 |

80 |

2.2 |

< 0.1 |

- |

|

TPO |

√ |

0.55 |

3 |

70-90 |

2 |

- |

- |

|

TPU |

√ |

0.75 |

2-3 |

70-100 |

2 |

< 0.02 |

- |

1. Foundry industry:

In this process, the wax mold is repeatedly immersed in the clay. These outer layers form the mold. When the wax is melted, the molten metal can be poured into it. Dry air (very low vapor pressure) is better than others. The heating source is more commonly used to dry the clay layer, because the dry air will not deform the wax mold. The use of a hygroscopic dehumidifier can stabilize the operating cost of foundries in the foundry industry and increase the production volume without slowing down the production pace in the wet months, and the process drying time can be shortened by 50%.

2. Dehumidification and drying of plastic raw material resin:

All plastic raw material resins have a certain degree of hygroscopicity. When the plastic raw material particles are extruded, the moisture is heated and evaporated by the plastic raw material dehumidifier. These vapors will cause cracks in the structure and appearance of the plastic material. The desiccant dryer can reduce the humidity in the plastic raw materials and improve the quality of the finished product.

Honeycomb Dehumidifying dryer;This is a device used to dehumidifying plastic resin to achieve drying. For example,

POM,ABS,TPE,PAL,ABS,CAB,EVA(2),EVOH,LM(4),LCP,PA11,PA6.46.6,PAI,PAR,PBT,

PC,PC/ABS,PC/PBT,PE.HDEPE,LDPE black3%,PE.HDEPE.LDPE black40%,PEEK,PE(1),

PEN,PES,PET,PETG,PI,PMMA,POM,PP,PPO,PPS,PS,[GPPS.EPS.HIPS],PSU,PIT,PUR,

PVC,SAN,SB,TPE,TPE,TPO,TPU,

Dehumidifier dryerand other plastic resins must be dehumidified and dried during the production process to improve the quality of the finished product.

Product alias:Plastic dehumidifier,Plastic dryer,Plastic dehumidifier dryer,Honeycomb Dehumidifier,Resin dryer, resin dehumidifier, Honeycomb Dehumidifying dryer,Honeycomb Dehumidifying dryer |

Honeycomb Dehumidifying dryer Precautions

1. Under normal circumstances, the dehumidifier should be placed in the center, leaving enough space around, and the air inlet and outlet of the dehumidifier should not be covered by obstacles to keep the air unblocked.

2. Do not pull the power cord of the dehumidifier forcefully to move the dehumidifier during use.Honeycomb dehumidifier dryer

3. When using the dehumidifier, the airtightness of the room should be good, otherwise, the dehumidification effect will not be obvious, and it will increase the load of the dehumidifier and affect the service life of the dehumidifier.

4. At present, most dehumidifiers on the market are equipped with computer automatic control systems, with four-speed fuzzy control gears. Except for the first gear when shutting down, they have suitable humidity (relative humidity: 70%-60%) and dry (relative humidity: 60%-50%) and continuous dehumidification (relative humidity: the lowest can reach 35%). When the indoor humidity is higher than the humidity of the corresponding selected gear, the machine will automatically start dehumidification; when the water tank is full, the machine will automatically stop working, and The water level indicator light is on to remind that the water tank is full, and the water must be poured out before the machine can operate again.

5. When the machine body must be moved, unplug the power cord first, and then pour out the water in the water storage bucket. After moving the dehumidifier, it is best to let it stand for 4 to 6 hours before turning it on. Because the compressor pipeline of the dehumidifier contains refrigerant, after being moved, the refrigerant can only return to its original position after a period of time.

Dehumidifying dryer

Honeycomb Dehumidifying dryer Maintenance:

1. Honeycomb Dehumidifying dryerCheck the parts regularly, 1-2 times a month. The inspection items are whether the worm, bearing, shaft seal and other movable parts are flexible in rotation and wear. Any defects should be repaired in time for normal use.

2.Honeycomb Dehumidifying dryer Electrical control parts should be kept clean and sensitive, and faults should be repaired in time.

3.Honeycomb Dehumidifying dryer When one use is completed or work is stopped, the remaining materials should be taken out of the plastic drying and mixing machine, and the remaining powder in each part of the machine should be cleaned. If it is out of service for a long time, the machine must be wiped clean and covered with a tarp cloth.

4.Honeycomb Dehumidifying dryer When assembling and disassembling the mixing paddle of the plastic drying color mixing machine, it should be disassembled, steadily installed, and handled gently to avoid deformation and damage.

Correct operation for Honeycomb Dehumidifying dryer:![Honeycomb Dehumidifying dryer,Plastic dehumidifier,Plastic dryer,Plastic dehumidifier dryer,Honeycomb Dehumidifier,Resin dryer, resin dehumidifier, Honeycomb Dehumidifying dryer,POM,ABS,TPE,PAL,ABS,CAB,EVA(2),EVOH,LM(4),LCP,PA11,PA6.46.6,PAI,PAR,PBT,PC,PC/ABS,PC/PBT,PE.HDEPE,LDPE black3%,PE.HDEPE.LDPE black40%,PEEK,PE(1),PEN,PES,PET,PETG,PI,PMMA,POM,PP,PPO,PPS,PS,[GPPS.EPS.HIPS],PSU,PIT,PUR,PVC,SAN,SB,TPE,TPE,TPO,TPU,Honeycomb Dehumidifying dryer](/d/file/p/2020/09-12/30d0412e53723c2c1a50a8e1ffcaf736.jpg) 1. Before starting up, check the power distribution of all equipment and pipelines before work. If there are hidden dangers, remove them and deal with them in time.

2. Clean the air inlet filter of the heater.

3. When the temperature of the imported heat transfer oil of the main engine rises to 100-120℃, the induced air can be started.

4. The inlet temperature of the cloth bag can reach 70℃ or higher, which can be opened for stirring, stirring, and the number of rotations is appropriate.

5. Air pressure: main machine inlet 6-10Mpa, cloth bag inlet, main machine outlet 20-26Mpa, cloth bag outlet 36-40Mpa.

6. Unloading will start within 15 minutes when the machine is turned on and the unloading cannot be stopped for any reason, until the material in the bag box is unloaded after the machine stops.

7. Each shift must have a special person to watch the instrument on the panel, and if there is an abnormality, and find it out in time, the watcher can not leave without authorization until the machine stops.

8. The feeding personnel should carefully observe the material during feeding to avoid foreign matter in the material and cause accidents.

9. In normal work, the temperature of the heat transfer oil inlet cannot exceed 250°C, otherwise it will be opened and closed immediately to cool down.

10. When you hear noise in the host during work, stop it immediately, open the side door of the host, cool down and use a magnetic stick or touch it to clean out the foreign objects.

11. When the power is cut off during work, immediately close the thermal oil valve, open and close, and open the side door of the main engine to cool down.

12.Honeycomb Dehumidifying dryer When the power is cut, the cloth bag should be cleaned first. When the induced air is turned on, open the side door of the main unit to observe whether there is sparks. If necessary, spray with water (mist).

13. If there is a sudden change in the radiator oil bag pipeline (severe oil leakage, fire, etc.), the main oil guide valve should be closed immediately, and on-site fire fighting should be carried out immediately, and the boiler should be notified to cool down.

14. If sparks and explosions are found on the main engine and the bag box, immediately stop the induced air, open the closed valve, and close the valve of the main oil pipeline.

15. When you find sparks in the bag, take the time to unwind the material that is on fire, flush the bag with water, and control the amount of water to prevent the bag from being damaged even if the water level is too high.

16. Honeycomb Dehumidifying dryer Operators must keep a clear head when they are on the job, and keep patrolling and checking and not leaving the job without permission.

1. Before starting up, check the power distribution of all equipment and pipelines before work. If there are hidden dangers, remove them and deal with them in time.

2. Clean the air inlet filter of the heater.

3. When the temperature of the imported heat transfer oil of the main engine rises to 100-120℃, the induced air can be started.

4. The inlet temperature of the cloth bag can reach 70℃ or higher, which can be opened for stirring, stirring, and the number of rotations is appropriate.

5. Air pressure: main machine inlet 6-10Mpa, cloth bag inlet, main machine outlet 20-26Mpa, cloth bag outlet 36-40Mpa.

6. Unloading will start within 15 minutes when the machine is turned on and the unloading cannot be stopped for any reason, until the material in the bag box is unloaded after the machine stops.

7. Each shift must have a special person to watch the instrument on the panel, and if there is an abnormality, and find it out in time, the watcher can not leave without authorization until the machine stops.

8. The feeding personnel should carefully observe the material during feeding to avoid foreign matter in the material and cause accidents.

9. In normal work, the temperature of the heat transfer oil inlet cannot exceed 250°C, otherwise it will be opened and closed immediately to cool down.

10. When you hear noise in the host during work, stop it immediately, open the side door of the host, cool down and use a magnetic stick or touch it to clean out the foreign objects.

11. When the power is cut off during work, immediately close the thermal oil valve, open and close, and open the side door of the main engine to cool down.

12.Honeycomb Dehumidifying dryer When the power is cut, the cloth bag should be cleaned first. When the induced air is turned on, open the side door of the main unit to observe whether there is sparks. If necessary, spray with water (mist).

13. If there is a sudden change in the radiator oil bag pipeline (severe oil leakage, fire, etc.), the main oil guide valve should be closed immediately, and on-site fire fighting should be carried out immediately, and the boiler should be notified to cool down.

14. If sparks and explosions are found on the main engine and the bag box, immediately stop the induced air, open the closed valve, and close the valve of the main oil pipeline.

15. When you find sparks in the bag, take the time to unwind the material that is on fire, flush the bag with water, and control the amount of water to prevent the bag from being damaged even if the water level is too high.

16. Honeycomb Dehumidifying dryer Operators must keep a clear head when they are on the job, and keep patrolling and checking and not leaving the job without permission.

Product alias:Plastic dehumidifier,Plastic dryer,Plastic dehumidifier dryer,Honeycomb Dehumidifier,Resin dryer, resin dehumidifier, Honeycomb Dehumidifying dryer,Honeycomb Dehumidifying dryer |

|

|

+8613669807274

+8613669807274

+8613669807274

+8613669807274 wto-btb@wto-btb.com

wto-btb@wto-btb.com Tel: +8613669807274

Tel: +8613669807274 SMS: +8613669807274

SMS: +8613669807274