| Hopper Dehumidifing dryer Details description |

|

| product name:Hopper Dehumidifing dryer |

| release time:2020-09-12 |

| Numbering:Hopper desiccant dryer-001 |

| Brand:wto-btb |

| Price:¥By function |

| weight :By function |

| unit weight:Kg/set |

manufacturer:wto-btb |

| patent:wto-btb |

| Producing country:china |

simple description:Especially suitable for engineering plastic materials with strong moisture absorption. Such as PA, PET, PC, PBT, etc., among which optical-grade GCD-OP models can be used in the manufacturing process of optical-grade products such as lenses, LCD light guide plates, optical discs, etc., under ideal conditions the lowest dew point can reach -40℃ .,

This is a device used to dehumidifying plastic resin to

achieve drying. For example,POM,ABS,TPE,PAL,ABS,CAB,

EVA(2),EVOH,LM(4),LCP,PA11,PA6.46.6,PAI,PAR,PBT,

PC,PC/ABS,PC/PBT,PE.HDEPE,LDPE black3%,PE.HDEPE.

LDPE black40%,PEEK,PE(1),PEN,PES,PET,PETG,PI,

PMMA,POM,PP,PPO,PPS,PS,[GPPS.EPS.HIPS],PSU,

PIT,PUR,PVC,SAN,SB,TPE,TPE,TPO,TPU,

Dehumidifier dryer and other plastic resins must be

dehumidified and dried during the production process to

improve the quality of the finished product. |

| Product alias:Hopper Dehumidifing dryer,Hopper desiccant dryer, European style desiccant dryer, vacuum dryer,Hopper dryer |

|

| Hopper Dehumidifing dryer Product introduction |

|

Hopper Dehumidifing dryer parameter

Hopper dryer

1. Use uniformly dispersed high-performance hot air diffusion device to keep the plastic drying temperature uniform and improve drying efficiency.

2. The special curved design of the hot air tube can avoid the accumulation of dust on the bottom of the electric heating tube to cause burning.

3. The proportional deviation indicating temperature controller is used to accurately control the temperature.

4. With overheating protection device, it can reduce accidents caused by man-made or mechanical failure.

5. The appearance is novel and bright.

|

model |

capacity(kg) |

electro-thermal

(kw) |

Fan(W) |

power supply(V) |

Dimensions

(cm) |

Base installation size(cm) |

net weight

(kg) |

|

NHD-12 |

12 |

1.8 |

50 |

380/3ф |

64*44*76 |

11*11*ф4 |

22 |

|

NHD-25 |

25 |

3.5 |

122 |

380/3ф |

76*50*104 |

16*16*ф6.2 |

34 |

|

NHD-50 |

50 |

4.5 |

157 |

380/3ф |

87*54*121 |

16*16*ф7 |

45 |

|

NHD-75 |

75 |

6.5 |

246 |

380/3ф |

94*60*131 |

16*16*ф7 |

56 |

|

NHD-100 |

100 |

6.5 |

246 |

380/3ф |

101*70*141 |

18*18*ф8 |

68 |

|

NHD-150 |

150 |

9 |

350 |

380/3ф |

110*74*162 |

20*20*ф8.2 |

78 |

|

NHD-200 |

200 |

12 |

350 |

380/3ф |

118*84*176 |

23*23*ф11.5 |

110 |

|

NHD-300 |

300 |

15 |

400 |

380/3ф |

142*100*183 |

27.5*27.5*ф12 |

152 |

|

NHD-400 |

400 |

15 |

400 |

380/3ф |

148*106*202 |

27.5*27.5*ф12 |

170 |

|

NHD-600 |

600 |

20 |

1000 |

380/3ф |

158*116*240 |

28*28*ф13.5 |

280 |

|

NHD-800 |

800 |

30 |

2200 |

380/3ф |

177*118*254 |

28*28*ф13.5 |

380 |

|

NHD-1000 |

1000 |

40.8 |

1100 |

380/3ф |

192*147*327 |

28*28*ф13.5 |

650 |

|

NHD-1500 |

1500 |

51 |

1500 |

380/3ф |

203*154*385 |

28*28*ф13.5 |

750 |

Note:

①The capacity of the dryer is based on the quality of the nylon 6 granular raw materials;

②The size of NHD-1000 and 1500 includes the size of the support tripod;

③The voltage specification of the machine is: 3Φ, 380V, 50Hz.

| Model |

Capacity (KG) |

HeatingPower

(KW) |

Blower

(W) |

Power

(V) |

Dimensions

(HxWxD,MM) |

Approx.Net Weight

(KG) |

| HGB-6 |

6 |

1.5 |

150 |

1φ 220V |

490x490x785 |

25 |

| HGB-12 |

12 |

2 |

160 |

1φ 220V |

540x435x850 |

35 |

| HGB-25 |

25 |

3 |

150 |

1φ 220V |

605x560x1240 |

50 |

| HGB-50 |

50 |

3.9 |

160 |

3φ 380V |

706x594x1410 |

75 |

| HGB-75 |

75 |

4.2 |

240 |

3φ 380V |

751x649x1520 |

105 |

| HGB-100 |

100 |

6.2 |

240 |

3φ 380V |

817x581x1670 |

125 |

| HGB-150 |

150 |

7 |

240 |

3φ 380V |

868x710x1800 |

160 |

| HGB-200 |

200 |

11 |

300 |

3φ 380V |

995x830x1930 |

210 |

| HGB-300 |

300 |

18 |

320 |

3φ 380V |

1160x975x2280 |

330 |

| HGB-400 |

400 |

20 |

360 |

3φ 380V |

1220x990x2330 |

365 |

| HGB-500 |

500 |

22 |

750 |

3φ 380V |

1150x1045x2430 |

385 |

| HGB-600 |

600 |

24 |

750 |

3φ 380V |

1210x1070x2540 |

400 |

| HGB-800 |

800 |

30 |

1500 |

3φ 380V |

1390x1120x2730 |

600 |

| HGB-1000 |

1000 |

36 |

1500 |

3φ 380V |

1525x1425x3670 |

650 |

| HGB-1200 |

1200 |

36 |

1500 |

3φ 380V |

1600x1510x3722 |

835 |

| HGB-1500 |

1500 |

40 |

2200 |

3φ 380V |

1730x1680x3880 |

900 |

| HGB-1800 |

1800 |

45 |

2200 |

3φ 380V |

1835x1680x4060 |

1005 |

| HGB-2000 |

2000 |

45 |

2200 |

3φ 380V |

1870x1710x4415 |

1130 |

| HGB-3000 |

3000 |

50 |

3700 |

3φ 380V |

2080x1920x4520 |

1650 |

| HGB-3500 |

3500 |

50 |

3700 |

3φ 380V |

2141x1976x4863 |

2120 |

| HGB-4000 |

4000 |

60 |

3700 |

3φ 380V |

2192x2040x4936 |

2870 |

| HGB-5000 |

5000 |

60 |

5500 |

3φ 380V |

2355x2160x5120 |

3510 |

Product alias:Hopper Dehumidifing dryer,Hopper desiccant dryer, European style desiccant dryer, vacuum dryer,Hopper dryer,Hopper Dehumidifing dryer |

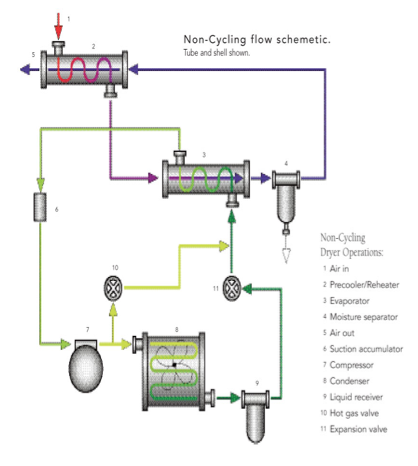

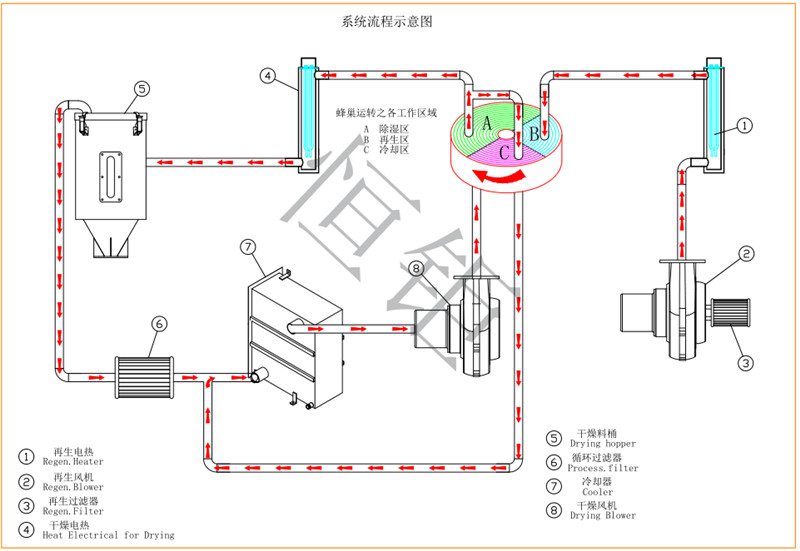

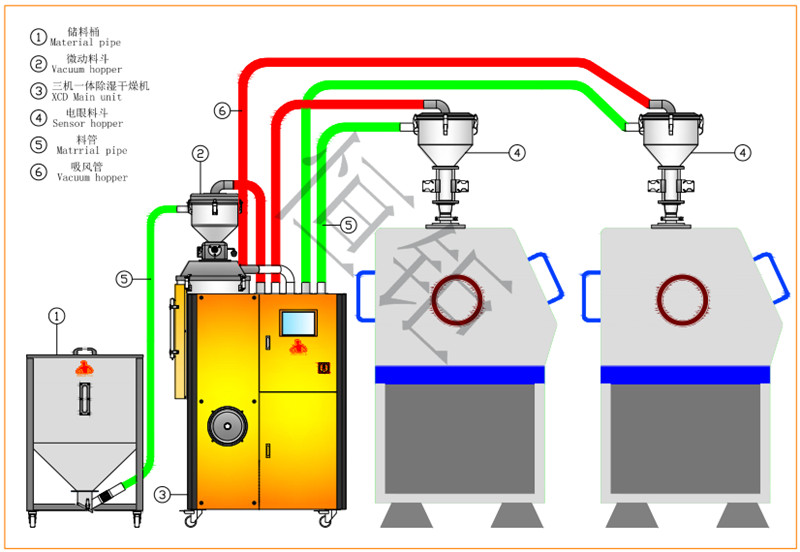

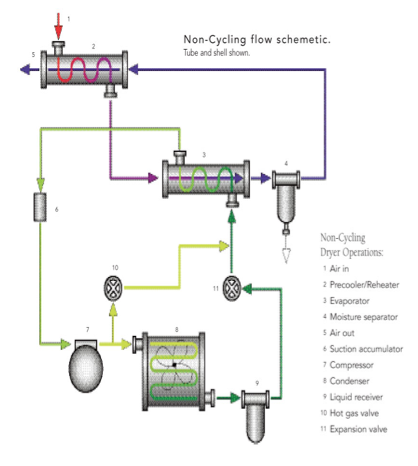

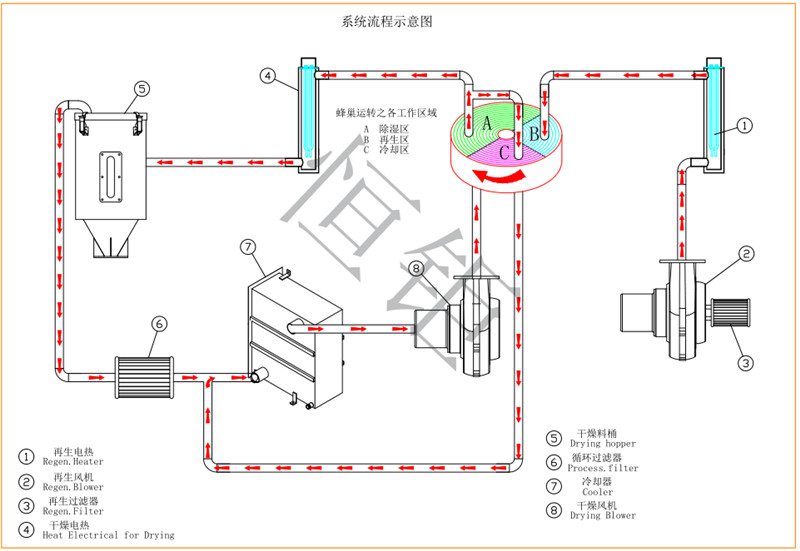

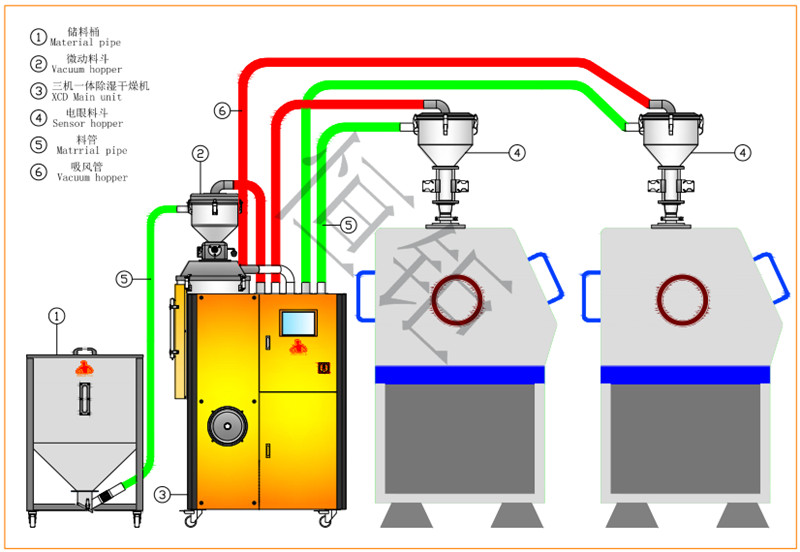

Hopper Dehumidifing dryer Equipment principle

1. Adopt a high-performance hot air diffusion device that evenly disperses hot air to keep the plastic drying temperature uniform and increase drying efficiency.

2. The special hot air elbow design can avoid the accumulation of dust on the bottom of the electric heating tube and cause burning.

3. All kinds of dehumidification dryer models can provide preheating timing device, microcomputer control, and double-layer insulation barrel selection.

4. The material barrel and internal parts are all made of stainless steel, and the material barrel is separated from the bottom, which is convenient for material cleaning and rapid material change.

5. The proportional deviation indicating temperature controller is used to accurately control the temperature.

6. There are double overheating protection devices, which can reduce accidents caused by man-made or mechanical failures.

7, 0-99 hours timed automatic startup, providing intermittent drying method to achieve the purpose of power saving.

Hopper Dehumidifing dryer It adopts double condenser structure to ensure lower return air temperature and dew point.

1. Hopper Dehumidifing dryer Adopt P.I.D temperature control system, which has regeneration temperature setting and actual temperature display screen.

2. Adjustable rotating speed control of honeycomb wheel.

3. The honeycomb can reach a dew point of -40°C, and can reach a dew point of -50°C or even lower when the configuration is enhanced.

4. Optional PLC control with LCD touch man-machine interface.

5. Dew point meter that can monitor the dehumidification effect of the machine at any time is optional.

6. The machine occupies a small area and is easy to move, and the machine can be replaced at will.

Product alias:Hopper Dehumidifing dryer,Hopper desiccant dryer, European style desiccant dryer, vacuum dryer,Hopper dryer |

Hopper Dehumidifing dryer application

Since most engineering plastics are hygroscopic, coupled with the influence of weather and regional climate, it is easy to cause the plastic pellets to be excessively wet and fail to achieve the molding effect. In addition, the plastic raw materials are different in the previous granulation process, so the air moisture content and hygroscopicity are also different. Therefore, when molding, it is easy to produce bubbles, silver bars, poor transparency, cracks, and poor stability, which seriously affect product quality. The air pipeline of the desiccant dryer adopts a closed circulation system, which can not be affected by the external weather. The material can be dried well in dry weather or wet weather, without reversing moisture, and the product quality is high.

The desiccant dryer first draws the air in the environment to remove the moisture in the air under low dew point, and then heats the dried air into one or more standard drying hoppers, which can improve the drying efficiency and shorten the drying time. If a traditional hot air blower uses moisture with external air to dry the material, it is difficult to achieve the drying effect. In addition, when the plastic is taken out of the moisture-proof sealed packaging bag and exposed to the atmosphere, it will begin to absorb moisture from the atmosphere. Traditional hot air blowers cannot prevent the plastic from continuing to absorb moisture, and the drying effect is poor.

Especially suitable for engineering plastic materials with strong moisture absorption. Such as PA, PET, PC, PBT, etc., among which optical-grade GCD-OP models can be used in the manufacturing process of optical-grade products such as lenses, LCD light guide plates, optical discs, etc., under ideal conditions the lowest dew point can reach -40℃ .

1. Foundry industry:

In this process, the wax mold is repeatedly immersed in the clay. These outer layers form the mold. When the wax is melted, the molten metal can be poured into it. Dry air (very low vapor pressure) is better than others. The heating source is more commonly used to dry the clay layer, because the dry air will not deform the wax mold. The use of a hygroscopic dehumidifier can stabilize the operating cost of foundries in the foundry industry and increase the production volume without slowing down the production pace in the wet months, and the process drying time can be shortened by 50%.

2. Dehumidification and drying of plastic raw material resin:

All plastic raw material resins have a certain degree of hygroscopicity. When the plastic raw material particles are extruded, the moisture is heated and evaporated by the plastic raw material dehumidifier. These vapors will cause cracks in the structure and appearance of the plastic material. The desiccant dryer can reduce the humidity in the plastic raw materials and improve the quality of the finished product.

Hopper Dehumidifing dryer;This is a device used to dehumidifying plastic resin to achieve drying. For example,

POM,ABS,TPE,PAL,ABS,CAB,EVA(2),EVOH,LM(4),LCP,PA11,PA6.46.6,PAI,PAR,PBT,

PC,PC/ABS,PC/PBT,PE.HDEPE,LDPE black3%,PE.HDEPE.LDPE black40%,PEEK,PE(1),

PEN,PES,PET,PETG,PI,PMMA,POM,PP,PPO,PPS,PS,[GPPS.EPS.HIPS],PSU,PIT,PUR,

PVC,SAN,SB,TPE,TPE,TPO,TPU,

Dehumidifier dryerand other plastic resins must be dehumidified and dried during the production process to improve the quality of the finished product.

Product alias:Hopper Dehumidifing dryer,Hopper desiccant dryer, European style desiccant dryer, vacuum dryer,Hopper dryer,Hopper Dehumidifing dryer |

Hopper Dehumidifing dryer Precautions

Maintenance and maintenance of hopper desiccant dryer:

(1) Ensure that the hot air is clean.

(2) Measures should be taken to prevent coke dust and avoid backflow of hot air.

(3) For viscous materials, measures should be taken to minimize wall sticking.

(4) The exhaust air temperature is not allowed to exceed the requirements to ensure product quality and safety.

(5) During the drying process of the material, all parts of the equipment in contact with the material must be easy to clean and sterilize.

(6) In order to improve the solubility, instant solubility, and dry products, they should be continuously discharged from the drying chamber quickly and packaged after cooling.

Hopper Dehumidifing dryer Maintenance:

1. Hopper Dehumidifing dryerCheck the parts regularly, 1-2 times a month. The inspection items are whether the worm, bearing, shaft seal and other movable parts are flexible in rotation and wear. Any defects should be repaired in time for normal use.

2.Hopper Dehumidifing dryer Electrical control parts should be kept clean and sensitive, and faults should be repaired in time.

3.Hopper Dehumidifing dryer When one use is completed or work is stopped, the remaining materials should be taken out of the plastic drying and mixing machine, and the remaining powder in each part of the machine should be cleaned. If it is out of service for a long time, the machine must be wiped clean and covered with a tarp cloth.

4.Hopper Dehumidifing dryer When assembling and disassembling the mixing paddle of the plastic drying color mixing machine, it should be disassembled, steadily installed, and handled gently to avoid deformation and damage.

Correct operation for Hopper Dehumidifing dryer:![Hopper Dehumidifing dryer,Hopper Dehumidifing dryer,Hopper desiccant dryer, European style desiccant dryer, vacuum dryer,Hopper dryer,POM,ABS,TPE,PAL,ABS,CAB,EVA(2),EVOH,LM(4),LCP,PA11,PA6.46.6,PAI,PAR,PBT,PC,PC/ABS,PC/PBT,PE.HDEPE,LDPE black3%,PE.HDEPE.LDPE black40%,PEEK,PE(1),PEN,PES,PET,PETG,PI,PMMA,POM,PP,PPO,PPS,PS,[GPPS.EPS.HIPS],PSU,PIT,PUR,PVC,SAN,SB,TPE,TPE,TPO,TPU,Hopper Dehumidifing dryer](/d/file/p/2020/09-12/a1db4bad89b3c38ba1a2a0fd8efe66d6.jpg) 1. Before starting up, check the power distribution of all equipment and pipelines before work. If there are hidden dangers, remove them and deal with them in time.

2. Clean the air inlet filter of the heater.

3. When the temperature of the imported heat transfer oil of the main engine rises to 100-120℃, the induced air can be started.

4. The inlet temperature of the cloth bag can reach 70℃ or higher, which can be opened for stirring, stirring, and the number of rotations is appropriate.

5. Air pressure: main machine inlet 6-10Mpa, cloth bag inlet, main machine outlet 20-26Mpa, cloth bag outlet 36-40Mpa.

6. Unloading will start within 15 minutes when the machine is turned on and the unloading cannot be stopped for any reason, until the material in the bag box is unloaded after the machine stops.

7. Each shift must have a special person to watch the instrument on the panel, and if there is an abnormality, and find it out in time, the watcher can not leave without authorization until the machine stops.

8. The feeding personnel should carefully observe the material during feeding to avoid foreign matter in the material and cause accidents.

9. In normal work, the temperature of the heat transfer oil inlet cannot exceed 250°C, otherwise it will be opened and closed immediately to cool down.

10. When you hear noise in the host during work, stop it immediately, open the side door of the host, cool down and use a magnetic stick or touch it to clean out the foreign objects.

11. When the power is cut off during work, immediately close the thermal oil valve, open and close, and open the side door of the main engine to cool down.

12.Hopper Dehumidifing dryer When the power is cut, the cloth bag should be cleaned first. When the induced air is turned on, open the side door of the main unit to observe whether there is sparks. If necessary, spray with water (mist).

13. If there is a sudden change in the radiator oil bag pipeline (severe oil leakage, fire, etc.), the main oil guide valve should be closed immediately, and on-site fire fighting should be carried out immediately, and the boiler should be notified to cool down.

14. If sparks and explosions are found on the main engine and the bag box, immediately stop the induced air, open the closed valve, and close the valve of the main oil pipeline.

15. When you find sparks in the bag, take the time to unwind the material that is on fire, flush the bag with water, and control the amount of water to prevent the bag from being damaged even if the water level is too high.

16. Hopper Dehumidifing dryer Operators must keep a clear head when they are on the job, and keep patrolling and checking and not leaving the job without permission.

1. Before starting up, check the power distribution of all equipment and pipelines before work. If there are hidden dangers, remove them and deal with them in time.

2. Clean the air inlet filter of the heater.

3. When the temperature of the imported heat transfer oil of the main engine rises to 100-120℃, the induced air can be started.

4. The inlet temperature of the cloth bag can reach 70℃ or higher, which can be opened for stirring, stirring, and the number of rotations is appropriate.

5. Air pressure: main machine inlet 6-10Mpa, cloth bag inlet, main machine outlet 20-26Mpa, cloth bag outlet 36-40Mpa.

6. Unloading will start within 15 minutes when the machine is turned on and the unloading cannot be stopped for any reason, until the material in the bag box is unloaded after the machine stops.

7. Each shift must have a special person to watch the instrument on the panel, and if there is an abnormality, and find it out in time, the watcher can not leave without authorization until the machine stops.

8. The feeding personnel should carefully observe the material during feeding to avoid foreign matter in the material and cause accidents.

9. In normal work, the temperature of the heat transfer oil inlet cannot exceed 250°C, otherwise it will be opened and closed immediately to cool down.

10. When you hear noise in the host during work, stop it immediately, open the side door of the host, cool down and use a magnetic stick or touch it to clean out the foreign objects.

11. When the power is cut off during work, immediately close the thermal oil valve, open and close, and open the side door of the main engine to cool down.

12.Hopper Dehumidifing dryer When the power is cut, the cloth bag should be cleaned first. When the induced air is turned on, open the side door of the main unit to observe whether there is sparks. If necessary, spray with water (mist).

13. If there is a sudden change in the radiator oil bag pipeline (severe oil leakage, fire, etc.), the main oil guide valve should be closed immediately, and on-site fire fighting should be carried out immediately, and the boiler should be notified to cool down.

14. If sparks and explosions are found on the main engine and the bag box, immediately stop the induced air, open the closed valve, and close the valve of the main oil pipeline.

15. When you find sparks in the bag, take the time to unwind the material that is on fire, flush the bag with water, and control the amount of water to prevent the bag from being damaged even if the water level is too high.

16. Hopper Dehumidifing dryer Operators must keep a clear head when they are on the job, and keep patrolling and checking and not leaving the job without permission.

Product alias:Hopper Dehumidifing dryer,Hopper desiccant dryer, European style desiccant dryer, vacuum dryer,Hopper dryer,Hopper Dehumidifing dryer |

|

|

+8613669807274

+8613669807274

+8613669807274

+8613669807274 wto-btb@wto-btb.com

wto-btb@wto-btb.com Tel: +8613669807274

Tel: +8613669807274 SMS: +8613669807274

SMS: +8613669807274