plastic dryer |

|

|

|

plastic dryer |

More complete plastic resin desiccant dryer information |

source:Plastic pellet dryer Author:plastic dryer time:2020年09月18日 17:27:33 |

| plastic dryer,

Dehumidifying dryer,

Plastic pellet dryer,

plastic Dehumidifying dryer

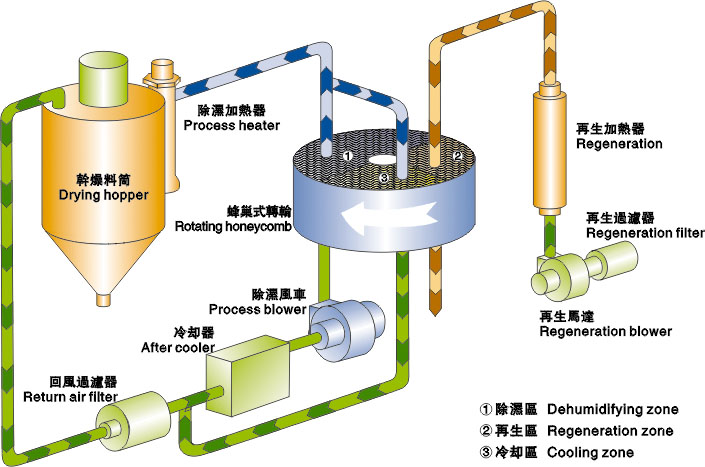

The concept of three-in-one dehumidification dryer: In the drying process of the material, firstly, the moisture on the surface of the material is heated and vaporized and removed by the vacuum equipment. The moisture on the surface of the material is gradually reduced due to vaporization, and a temperature difference is formed between the inside and the surface of the material. Under the action of the temperature difference, the internal moisture continuously diffuses to the surface and vaporizes after reaching the surface. In addition, in the vacuum drying process, there is a pressure difference at the same time, which makes the vaporized water molecules accelerate to move to the vacuum space. In the vacuum drying process, people always want to speed up the drying speed and shorten the drying time. However, the following factors affect the drying speed: The higher the degree of vacuum, the more conducive to the vaporization of moisture at a lower temperature, but too high a vacuum is unfavorable to heat conduction and will affect the heating effect of the material. In order to increase the drying speed of materials, the vacuum degree should be considered comprehensively according to the characteristics of the materials. Generally, the vacuum degree should not be less than 1×104Pa; the condition of the material to be dried (such as material shape, size, stacking method), the moisture content, density, viscosity and other properties of the material itself. Generally, if the material particles are fine and uniform, the pile is loose, and the thickness is thin, the internal moisture is easy to diffuse. If the initial temperature of the material is increased, the pre-treatment by vacuum filtration, and the moisture content of the material is reduced, the vacuum drying speed can be increased. The difference between rotary honeycomb and rotary molecular sieve:  The core component of the honeycomb wheel dehumidification dryer series, the honeycomb wheel is a honeycomb-shaped desuperheating wheel that continuously rotates slowly. The wheel is composed of a corrugated medium made of special ceramic fiber composite high-temperature materials; both sides of the wheel The baffle made of silicone rubber with high sealing performance divides the entire surface into two sectors, which has strong moisture absorption and stability. It can dehumidify air moisture and dew point up to -50℃. It is called the runner honeycomb. The core component of the rotary molecular sieve desiccant dryer is a synthetic desiccant product with strong adsorption to water molecules. The pore size of the molecular sieve is controlled by the different processing technology. It is an aluminosilicate compound with a cubic lattice, which is mainly composed of silicon and aluminum connected by oxygen bridges to form an open framework structure. The dehumidification of air moisture can only reach -30℃. It is called molecular sieve. The dew point temperature refers to the temperature at which the moisture contained in the gas is cooled to condense into water droplets, and is a measure of the degree of dryness (humidity) of the gas. The less moisture in the gas, the lower the dew point temperature. The dew point of a good desiccant dryer should reach a dew point temperature of -40°C. The above description recommends the use of customer choice runner honeycomb. Reason 1: The dew point of the air dehumidification of the runner honeycomb can easily reach -40℃, and the configuration enhancement can reach -50℃, which is relatively stable. The service life is 8 years, and it can be used for 8-10 years under good maintenance. Reason two: the air dehumidification dehumidifier of the runner molecular sieve is unstable. According to the information provided by market users. The air dehumidification dew point of the new rotor molecular sieve can only reach -32℃. After one year of use, the dew point will drop to -20℃. After one and a half years of use, the dew point will drop to -10℃. Used for two years. The structure of the wheel type honeycomb A honeycomb wheel structure of a plastic particle dehumidifier. One end of the honeycomb wheel is provided with an upper cover, and the other end is provided with a lower cover. The top surface of the upper cover is provided with a dehumidification air outlet and a regeneration exhaust port And a dehumidification air return port, the inner surface is provided with an exhaust area corresponding to the regeneration exhaust port, and a return area corresponding to the dehumidification air return hole, and an air outlet area corresponding to the dehumidification air outlet; the lower cover is provided with a In the regeneration zone, there is a hot air inlet corresponding to the regeneration zone, the lower cover is provided with a cooling zone, and there is an air outlet corresponding to the cooling zone, and the lower cover is provided with a dehumidification zone and an air inlet corresponding to the dehumidification zone. As for the honeycomb wheel, it is divided into a regeneration zone, a cooling zone, and a drying zone according to the position in use. The regeneration zone refers to the area between the exhaust zone corresponding to the upper cover and the regeneration zone of the lower cover. The cooling zone corresponds to the part between the reflux zone of the upper cover and the cooling zone of the lower cover; the drying zone corresponds to the air outlet zone of the upper cover and the dehumidification of the lower cover The part between the zones is characterized in that a driving device is provided to drive the honeycomb wheel to rotate. The driving device is composed of a motor and a gear set, and the gear set is equipped with a rotating shaft; the dehumidification air outlet of the upper cover body , The regeneration exhaust port and the dehumidification air return port are provided with intermediate slots, and the exhaust area, the return area and the inner surface of the air outlet area are equipped with heat insulation layers; and the regeneration area of the lower cover There is a groove between the cooling zone and the dehumidification zone, and there is a heat insulation layer on the inner surface of the regeneration zone, the cooling zone and the dehumidification zone. In addition, there is a groove between the air outlet zone and the return zone of the upper cover. Backflow tube. Working principle of plastic dehumidifier  The core component of the honeycomb wheel dehumidifier series is a continuously slowly rotating honeycomb-shaped desuperheating wheel, which is composed of corrugated medium made of special composite heat-resistant materials; both sides of the wheel are made of silicon with high sealing performance The rubber partition divides the entire surface into two sectors: 270 degree processing sector; 90 degree regeneration recovery sector. When the humid air that needs to be dehumidified enters the 270-degree treatment area of the runner, the water vapor of the humid air is absorbed by the active silica gel of the runner and enters the 90-degree regeneration reduction sector. The dry air is processed and sent to the drying material by the fan. Bucket, there is an appropriate amount of highly hygroscopic plastic material inside the hopper. The dehumidified and dried air adsorbs the internal moisture of the plastic material. As the adsorbed water increases, the runner restores its moisture absorption capacity and completes the regeneration process. Under the action of the drying fan, the air is dehumidified It is sent to the dehumidifier, and the dehumidification sector gradually becomes saturated. Driven by the speed-regulating motor, it slowly transfers to the slow cooling zone. The high temperature air blown in the regeneration zone in the reverse direction causes the adsorbed water in the runner to be removed. After attached, enter the dehumidification area for dehumidification. The dehumidification and regeneration process mentioned above The air is constantly being dried, the runner is continuously regenerated, and the cycle starts again and again, thus ensuring the continuous stability of the dehumidifier. The runner speed is 8~12 rpm, and the required power is very small. The outlet air parameters of the dehumidifier depend only on the inlet Air parameters and regeneration energy control. Wheel dehumidification The working principle and advantages of the dehumidifier ensure the continuous and stable dehumidification state of the dehumidifier. Rotary honeycomb features Rotary honeycomb corrugated media contains moisture absorbent. This design has a compact structure and can provide a huge surface area for wet air and hygroscopic media to fully contact. Thereby greatly improving the dehumidification efficiency of the dehumidifier. How to use plastic dehumidifier The plastic dehumidifier is a fully automatic closed dehumidifier that is matched with a hopper dryer and an automatic suction machine to dehumidify and dry plastic materials with strong moisture absorption. Prepared. The traditional method of using heat to dry its plastic materials. With the pursuit of high quality in the market, engineering plastics such as PA, PC, PBT, PET and other highly hygroscopic plastics cannot meet market demand by using traditional methods. And "Shenzhen Jiujing Machinery Manufacturing Factory" is the first batch to develop a plastic material with strong hygroscopicity. Dehumidify and dry. The dehumidification and drying process of the raw materials is carried out in a fully enclosed state with a low dew point of -40°C, and the dehumidified plastic raw materials will not contact the outside air. So as to meet the most ideal needs of the market, it is the first and most plastic dehumidifier in the high-precision plastic industry. The air pipes of the plastic dehumidification dryer adopt a closed circulation system and are equipped with filters, so they are not affected by the external climate and Prevent dust from causing pollution in the factory and improve the working environment. The determinants of a good drying efficiency are: drying temperature (Drying Temperature), drying time (Residence time), airflow (Airflow), and dew point (Dew point). These four factors are interlinked, and any change in conditions will Affect the drying effect. Drying temperature refers to the temperature of the air entering the drying barrel. Due to its physical properties, such as molecular structure, specific gravity, specific heat, moisture content and other factors, the drying temperature has certain restrictions. If the temperature is too high, the raw material Part of the additives volatile or agglomerated, too low will make some crystalline raw materials unable to reach the required drying conditions, such as: PC/120℃, ABS/80~95℃. In addition, insulation and heat preservation are required in the selection of dry barrels to avoid loss of drying temperature, resulting in insufficient drying temperature or waste of energy. Drying time refers to the pre-drying time of raw materials before molding. Too long drying time will cause raw materials to deteriorate or condense or waste energy. Too short drying time will cause excessive moisture content. For example: PC/3-4 hours, ABS/3-4 hours. The air volume is the only medium that takes away the moisture in the raw materials, and the air volume will affect the dehumidification effect. Too much air volume will cause the return air temperature to be too high, resulting in overheating (over heat) and affecting the stability of the dew point. Too small air volume will not completely take away the moisture in the raw materials. The air volume also represents the dehumidification capacity of the dehumidifier dryer. The dew point temperature refers to the temperature at which the moisture contained in the gas is cooled to condense into water droplets, and is a measure of the degree of dryness (humidity) of the gas. The less moisture in the gas, the lower the dew point temperature. The dew point of a good desiccant dryer should reach a dew point temperature of -40°C. advantage: 1. It adopts LED interface display system and automatic fault display function. 2. Dehumidification wheel, long service life. 3. Suitable for general and optical dehumidification and drying 4. Motor reverse phase and overload protection 5. With over-temperature alarm and fault display function. plastic dryer, Dehumidifying dryer, Plastic pellet dryer, plastic Dehumidifying dryer |

| Dehumidification dryer | gravimetric blender | granules mixing machine |

|

|

|

| Links: | plastic dryer | Dehumidifying Dryer | gravimetric blender | beryllium copper | Central feeding system |

| contact us: | Mr. Li | QQ: | 1251609588 | Phone: | +8613669807274 | E-mail: | wto-btb@wto-btb.com |

| Ask for a quotation |

WhatsApp +8613669807274

+8613669807274

|

Wechat +8613669807274 +8613669807274 |

wto-btb@wto-btb.com

wto-btb@wto-btb.com |

Tel: +8613669807274

Tel: +8613669807274 |

SMS: +8613669807274

SMS: +8613669807274 |

| Website name:Plastic dryer Copyright:Plastic dryer |

| Search industry:plastic dryer,Dehumidifying dryer,Resin dryer,plastic Dehumidifying dryer ©2007-2029 @ |