plastic dryer |

|

|

|

Dehumidifying dryer encyclopedia |

source:plastic dryer Author:plastic dryer time:2020年09月10日 10:16:55 plastic dryer, Dehumidifying dryer, resin dryer, plastic Dehumidifying dryer |

||

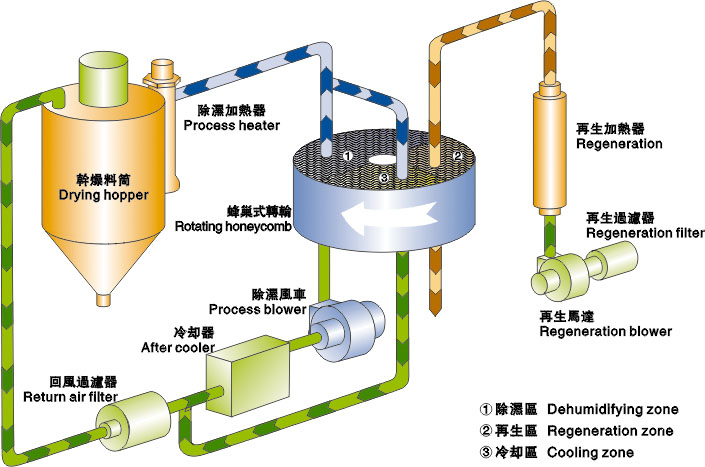

Dehumidifying dryer composition:1. Dehumidifying dryer The two air streams act on the runner at the same time, and with the rotation of the runner, the moisture in the air is continuously adsorbed and desorbed by the regeneration air to be discharged, forming a stable low dew point air. It is heated to the drying temperature of the plastic and blown into the drying barrel to form a closed loop to dry the raw materials. Plastic dehumidifying dryer model:Plastic dehumidifying dryer use:Mainly used for highly waterproof special plastics and resins,This is a device used to dehumidifying plastic resin to achieve drying. For example, Plastic dehumidifying dryer Reason for use:In the plastic processing industry, the products will have shrinkage, silver streaks, bubbles, cracks, melting, poor transparency and other problems. The main reason for this poor quality is that no plastic is produced. Fully dry before molding. Industrial plastics Such as:POM,ABS,TPE,PAL,ABS,CAB,EVA(2),EVOH,LM(4),LCP,PA11,PA6.46.6,PAI,PAR,PBT,PC,PC/ABS,PC/PBT,PEEK,PE(1),PEN,PES,PET,PETG,PI,PMMA,POM,PP,PPO,PPS,PS, PSU,PIT,PUR,PVC,SAN,SB,TPE,TPE,TPO,PE.HDEPE.LDPE black40%,[GPPS.EPS.HIPS], PE.HDEPE,LDPE black3%,TPU etc. are highly hygroscopic. Because water enters the plastic particles, traditional hot air dryers cannot completely dry them. . Practice has proved that reducing the dew point of the dry air to below -40°C and controlling the heat blowing through the surface of the wet resin can reduce its water content to below 0.02%. When closing the mold. Three-in-one sealed desiccant dryer. The circulation system completely absorbs moisture and heats the air, and the dry air quickly separates the moisture from the resin to achieve the effect of drying and drying. Plastic dehumidifying dryer working principle:Dehumidifying dryer Drying unit:The hot and humid air in the drying barrel is cooled and blown into the honeycomb treadmill. The moisture in the air is absorbed by the treadmill and then deodorized by the regenerated hot air. The two airflows act on the slider at the same time, and as the flow channel rotates, the moisture in the air is continuously absorbed and absorbed by the regenerated air, thereby releasing free air. Stable low dew point, the heated plastic blows the drying temperature into the drying drum, forming a closed cycle to dry the material.

Dehumidifying dryer Suction part:Suction material is sucked from the barrel or other silo container into the dry barrel. When the magnetic switch of the vacuum hopper detects that there is no material, the suction motor operates to generate a vacuum in the vacuum hopper. The material in the barrel is sucked into the vacuum hopper due to the air pressure difference, the suction engine stops running at the end of this time, and the material falls into the drying barrel due to its own weight. The dried material is sucked from the drying barrel into the electric funnel installed in the injection molding machinePlastic dehumidifying dryer Features:1. It integrates three functions of dehumidification, drying and feeding in two stages;2. The dehumidifier is equipped with a roller device, which can provide stable air with low dew point, which can reach below -40℃; 3. The stainless steel double-layer thermal insulation drying box adopts the bottom blowpipe design to help the materials dry evenly and effectively prevent heat loss; 4. The feed system is equipped with a shut-off valve to ensure that there is no raw material in the feed pipe. 5. The closed-loop feeding system can prevent the raw materials from being contaminated or wetted; 6. The combination of optical grade GCD-OP type and electric boiling hopper can eliminate fine powder in raw materials and avoid pollution during the casting process of optical grade products. 7. The optical-grade GCD-OP sample system is equipped with high-precision and high-efficiency filters, which can efficiently filter dust ions up to 0.3μm, with a filtration rate of up to 99.9%. ; 8. You can purchase PLC control with LCD touch man-machine interface, centralized and convenient operation, and the whole machine can be controlled and run automatically; 9. You can buy a dew point detector; Dehumidifying dryer Relative humidity:At the same temperature, the percentage of actual water vapor density and saturated vapor density in the air is the relative humidity of the air.Plastic dehumidifying dryer Dew point:Dew point:Dehumidifying dryer the temperature at which saturated water vapor condenses in the air. When the relative temperature is 100%, the ambient temperature is the dew point temperature. The dew point temperature is lower than the ambient temperature, and the lower the condensing capacity, which means that the drier the air, the greater the dew point is not affected by temperature, and the greater the pressure!Under ideal conditions, the lowest dew point can reach -40°C. . Dehumidifying dryer operation guide:1.Dehumidifying dryer PurposeStrengthen equipment management, avoid operating errors in the production process, reduce personal injury accidents, and ensure safe and effective Operation drying system is running. 2. Dehumidifying dryer area It is suitable for the operation equipment and its operators of the drying system in the workshop. 3. Dehumidifying dryer Operating procedures  3.1 Dehumidifying dryer Preparation before starting 1) Before starting the dryer, check whether the circulating water is normal. 2) Check whether the connecting parts and the nuts of the sealing section are loose, if they are loose, please tighten the nuts to compress the packing And timely reinforcement. 3) Check whether the connection of the meter is normal and whether it can operate normally. 3.2 Boot steps 1) Dehumidifying dryer Turn on the power and press the Dryer/Reset button for 3 seconds to turn on equipment; 2) Dehumidifying dryer Temperature setting: press the SV/ key and use the up and down arrow keys Set the temperature, press the SV/ key again after setting to confirm recognize; 3) Dehumidifying dryer Adding raw materials: press the Drying Hopper button, Add raw materials to the material tube, press again to stop; 4) Dehumidifying dryer Raw material supply: press the NO.1 button to supply the barrel of the injection molding machineRaw materials, press again to stop. 3.3 Shutdown steps Turn off the raw material supply, press and hold the Dryer/Reset button for 3 seconds to stop the equipment and cut off the power supply. 4. Precautions during use  4.1 Input of raw materials: the following points should be noted before adding raw materials a). Dehumidifying dryer Close the valve of the manual unloading port to prevent feeding Raw materials Sprinkle,; b). Dehumidifying dryer Confirm that the drying cylinder is clean and free of residual materials to avoid mixing; c) When changing the color of raw materials, (such as black raw materials for white raw materials) application Use cotton cloth and medical alcohol to carefully clean the drying cylinder and raw material delivery pipeline to avoid Avoid products with different colors and other defects; d). When adding raw materials each time, make sure that a magnetic rack is put in the drying cylinder. and Ensure that the magnetic stand is clean and free of adsorption; 4.2. The supply of raw materials: when the injection molding machine is automatically supplied with materials, the manual Seal the material opening 4.3. Record filling: Every time raw materials are added, corresponding records should be filled in. Obviously record the raw materials Model, quantity, drying temperature, time and other parameters; 4.4. Drying quantity of raw materials: when receiving raw materials for drying, try to receive a suitable quantity of raw materials Dry it. Avoid running out of raw materials and repeated drying. When the production task is completed, the original The materials are discharged and returned to the warehouse. To ensure the accuracy of raw material inventory. 5. Dehumidifying dryer Equipment maintenance 1) Check whether the hose has fallen off, broken or leaked every month. 2) Check whether the screws and nuts of each part of the device are loose every month. 3) Every 3 months, check whether the terminals in the control box and the wiring connection part of the device are loose. 4) Clean the delivery filter every 3 months and replace the filter if necessary. 5) Check and repair the main motor every 6 months. Maintenance of plastic desiccant dryer:he desiccant dryer should be cleaned frequently and kept clean. The dehumidifier should be placed in the center of the room. The air inlet and outlet of the refrigerated dryer should not be blocked by obstructions, and the air filter should be cleaned. When the ambient temperature is lower than 15℃, the water droplets attached to the surface of the evaporator will freeze and the effect of the dehumidifier will be weakened. If the ambient temperature exceeds 40℃, the pressure in the system will increase and the compressor will overload. At this time, the overload protector The circuit should be cut off, otherwise the compressor motor will be damaged. So the best temperature range for dehumidifier is 15℃~40℃. If the humidity in the air is below 30%, it will be too dry and uncomfortable. Therefore, a reliable humidity controller will control it to maintain the range of 50% to 60%. When in use, close doors and windows as much as possible to achieve dehumidification in the room. The body of the desiccant dryer must be placed flat, not tilted or turned sideways, to avoid machine failure or abnormal noise.The water storage in the desiccant dryer is too full. In order to avoid overflowing and contaminating the ground, when you must move the body during operation, please unplug the power cord first, and then pour out the water in the water storage bucket. After moving the dehumidifier, it is best to put it statically for four to six hours before starting to use it. Because the compressor pipeline in the dehumidifier contains cold coal, it must take four to six hours to return the cold coal to its original position after being moved. Clean the air filter regularly (about once every two weeks) to maintain the dehumidification and dust removal efficiency and life of the machine. Clean the air filter and wash it with water below 40°C; it is better to clean it with detergent. After washing off the dust, rinse it with water, dry it in the shade and put it back into the body. When cleaning the body, wipe it gently with a damp cloth; avoid directly splashing water for cleaning, so as not to damage the electrical insulation. Adhesives on the surface of the body can be cleaned with soap and water. Avoid spraying with gasoline, petroleum spirit, solvent or spray insecticide to avoid peeling paint or discoloration. Do not use thin rods or iron wires to dig out the inside of the machine to avoid malfunction or danger. Please unplug the power cord to maintain the life of the machine when it is out of power, not used for a long time, or when traveling. (1) Ensure that the hot air is clean. (2) Measures should be taken to prevent coke powder and avoid backflow of hot air. (3) During the drying process of the material,Dehumidifying dryer all parts of the equipment in contact with the material must be cleaned and disinfected. (4) For sticky materials, measures should be taken to minimize sticking. (5) Dehumidifying dryer In order to improve the solubility, instant solubility, and dry products, they should be continuously discharged from the drying chamber quickly and packaged after cooling. (6) The exhaust air temperature is allowed to exceed the requirements to ensure product quality and safety. Dehumidifying dryer Do not use the machine in the following situations:1.Dehumidifying dryer There is a damaged line;2. To prevent electric shock, do not run the machine on a wet floor or after the machine is exposed to rain; 3. If the machine is damaged or disassembled, it should not be overhauled and installed by professional maintenance personnel; 4. During the operation of the machine, at least 1m of surrounding space is required. Please protect this device and flammable materials at least 3m away; 5. Avoid vibration and magnetic influence in the work area; plastic dryer, Dehumidifying dryer, resin dryer, plastic Dehumidifying dryer |

| Dehumidification dryer | gravimetric blender | granules mixing machine |

|

|

|

| Contact us: Mr. Li QQ:345156262 1251609588 Phone:+86-13669807274 E-mail:wto-btb@wto-btb.com |

| Website name:Dehumidifying dryer Copyright:Dehumidifying dryer |

| Search:plastic dryer,Dehumidifying dryer,Resin dryer,plastic Dehumidifying dryer ©2007-2029 @ |