plastic dryer |

|

|

|

plastic dryer |

| Plastic dryers (plastic dryers, resin dryers, resin dehumidifying dryers, plastic dehumidifying dryers) are the most effective and economical models for drying plastic raw materials. Plastic dryer is a machine that mainly dehumidifies and dries plastic or resin materials. It can dry raw materials that are wet due to packaging, transportation or recycling, and eliminate the problems of bubbles, silver lines, cracks and poor stability, which will affect product quality, thereby reducing waste. The main reason for these poor quality is that the plastic is not completely dried before molding. Engineering plastics, such as: PA, PET, PC, PBT, CA and other materials with strong hygroscopicity, because water will penetrate into the plastic particles, traditional hot air dryers cannot completely dry them. Practice has proved that reducing the dew point of the dry air to below -40°C while controlling the heat to be blown to the surface of the wet plastic particles can reduce the water content to below 0.02% before molding. Because the desiccant dryer is airtight. The air is completely dehumidified and heated in the circulation system, and the dry air quickly separates the moisture in the plastic particles completely, thereby achieving the effect of dehumidification and drying. The plastic dryer uses screws to push it up, separates and dehydrates, and then automatically loads and unloads. Its unique automatic feeding and discharging functions eliminate the need for manual discharging of traditional centrifuges. Convenient and fast, forming a higher level of automatic assembly line production, greatly saving manpower and improving work efficiency. Plastic dryer Dryer characteristics1. Adopt P.I.D temperature control system, precise temperature control;2. The unique down-blowing air pipe design can evenly distribute the hot air, keep the plastic dry, stabilize the temperature, and improve the drying efficiency; 3. Stainless steel double-layer insulation barrel and attached window; 4. Widely GHD-40U and above models are equipped with openable door; 5. Thermal overload protection device, safe and reliable; 6. Novel appearance and bright appearance; Plastic dryer working principleThe air blown by the drying fan becomes high-temperature dry air after drying and electric heating. Through the unique lower blowing tube design, the hot air is evenly dispersed in the thermal insulation barrel to dry the raw materials; optional hot air recovery device, the blown wind is filtered and then dried The wind blows out, forming a closed loop. Dehumidification and drying part: The hot and humid air coming back from the drying barrel is cooled and blown into the honeycomb runner. The moisture in the air is adsorbed by the runner and then desorbed by the regenerated heated air. The two airflows act on the runner at the same time, and with the rotation of the runner, the moisture in the air is continuously adsorbed and desorbed by the regeneration air to be discharged, forming a stable low dew point air, which is heated to The drying temperature of the plastic is blown into the drying barrel to form a closed cycle to dry the raw materials. Suction part: Suction is sucked into the dry bucket from the storage bucket or other storage silo container. When the reed switch of the vacuum hopper detects that there is no material, the suction motor runs to generate a vacuum in the vacuum hopper. The dried raw material is pumped from the drying material barrel to the electric eye hopper installed in the plastic molding machine.The plastic dryer uses screws to push it up, separates and dehydrates, and then automatically loads and unloads. Its unique automatic feeding and discharging functions eliminate the need for manual discharging of traditional centrifuges. Convenient and fast, forming a higher level of automatic assembly line production, greatly saving manpower and improving work efficiency. Plastic dryer What models

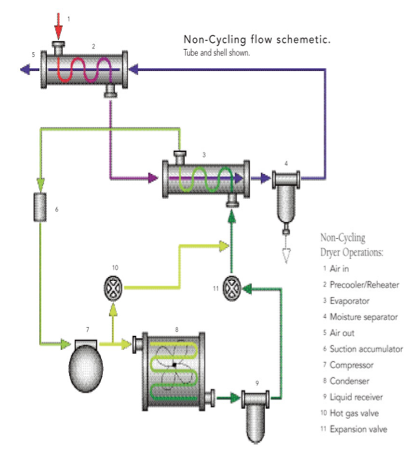

1.Plastic dryer-Dehumidifying DryersDehumidifying Dryers are designed to eliminate moisture in the plastic material before processing. Air is forced through a desiccant bed to make it extremely dry. This air is then heated to a specified temperature and fed into a Drying Hopper containing the material to be dried. This hot dry air draws the moisture out of the material; the saturated air is then fed out of the Drying Hopper and back through the desiccant bed again to remove the moisture before the cycle begins again. This desiccant has a limited ability to hold moisture before it needs to be regenerated (dried out). Typically, plastics processors use regenerative or twin tower dryers and in this case, when the desiccant bed has reached its moisture retaining capacity the airflow is automatically switched to the second desiccant bed to allow the drying process to continue. At the same time, the first desiccant bed is regenerated by heating to remove moisture, allowed to cool and it is then ready to absorb moisture again. 2.Plastic dryer-Rotary Wheel DryersRotary Wheel Dryers have been designed to address energy and other revenue draining issues presented by other types of drying. Rotor Dryers have a constant dew point whereas in twin desiccant dryers the dew point starts very low but increases as the desiccant bed saturates. When the airflow is switched to the second desiccant bed the dew point starts low again. Dew point control is a design feature of Rotor Dryers which allows the user to select a dew point suitable for the material to be processed and maintain this. This is a particularly beneficial feature as it virtually eliminates over drying. Some models of Rotor Dryers can save up to 40% in energy consumption when compared with the most efficient twin desiccant dryers, due to a lower regeneration temperature. This figure depends on the manufacturer of the dryer and can be less when only a 3-stage circuit technology is part of the design. 4 stage technology is available. Rotor Dryers utilise a rotating wheel which continuously puts dry desiccant into service due to its ability to regenerate moisture saturated desiccant in the same rotational cycle. Whereas the desiccant bed used in traditional Dehumidifying Dryers comprises desiccant beads and clay binder which degrades, Rotary Wheel Dryers employ in the region of 3 times the amount of pure desiccant. Desiccant beds on twin tower Dehumidifying Dryers regenerate at 320c, however in the Rotor Dryer it is an energy saving 140c. They do not use chilled water and they do not require compressed air. 3.Plastic dryer-Low Pressure Dryers or Vacuum DryersLow Pressure Dryers or Vacuum Dryers accelerate the plastic material drying process by using a vacuum to lower the boiling point of water from 100 °C to 56 °C. The moisture is rapidly extracted from the heated material. Leaving it in a condition to be moulded or extruded. Typically, these Low Pressure Dryers will dry materials in one-sixth of the time required by a desiccant dryer and the use of vacuum provides many process and revenue benefits when compared with conventional drying methods. This method of drying does not use desiccant at all and as such not only saves the expense but also saves the time required to maintain and replace desiccant. The low drying times offered by these machines reduces the risk of material degradation from exposing material to prolonged elevated drying times. 4.Plastic dryer-Compressed Air DryersCompressed Air Dryers, compact and light in weight these Dryers are designed to fit to the throat of the processing machine, although a free standing frame can be employed. Generally a method of drying employed for smaller throughput machines, the Compressed Air Dryer is similarly equipped with twin desiccant beds as the Dehumidifying Dryer. The main difference between the two is that air flow is generated by compressed air instead of electrically driven mechanical blowers. 5.Plastic dryer-Hot Air DryersHot Air Dryers are designed to remove surface moisture from no-hygroscopic material and to pre-heat material prior to processing. This pre heating is particularly useful in circumstances where material has been stored outside in the cold and is brought into more warm and humid conditions for processing. They usually comprise a well insulated hopper with an attached blower and heater. Hot air is blown through the material granules and the wet air is dispelled into the atmosphere. Plastic dryer-Applied material parametersIt is suitable for the drying and cooling of powdery and granular materials in chemical, pharmaceutical, food, food, dehydrated vegetables, minerals and other industries.

Plastic dryer The factors that affect the drying effect are:Drying temperature: Heat is the key to opening the joint force between water molecules and hygroscopic polymers. When it is higher than a certain temperature, the attraction between the water molecules and the polymer chain will be greatly reduced, and the water vapor will be taken away by the dry air.Dew point: In the dryer, first remove the humid air to make it contain very low residual moisture (dew point). Then, by heating the air to reduce its relative humidity. At this time, the vapor pressure of dry air is low. By heating, the water molecules inside the particles get rid of the binding force and diffuse to the air around the particles. Time: In the air around the particles, it takes a certain time for the absorption of heat and the diffusion of water molecules to the surface of the particles. Therefore, resin suppliers should specify the time it takes for a material to effectively dry at the proper temperature and dew point. Airflow: Dry hot air transfers heat to the particles in the drying silo, removes the moisture on the surface of the particles, and then sends the moisture back to the dryer. Therefore, there must be sufficient airflow to heat the resin to the drying temperature and maintain this temperature for a certain period of time. Plastic dryer maintainTurn on the power and check whether the voltage and surface of the high-efficiency plastic dryer are normal. After all, check the amount and concentration of the slurry in the slurry mixing barrel. If there is a problem, it should be cleaned in time.1. Before each operation, the operator should check whether the steam valve, compressed air and each range meter are normal. 2. Check whether the air pressure of the upper and lower airbag seals is below 0.1 ~ 0.15mpa. If the air pressure is too high, the seal will burst, and if it is too low, the powder will not leak from the seal, which will affect the output power and dry quality. 3. Check whether the upper and lower airbag seals have protrusions and the flat head screws are loose to prevent the material truck from crashing when it is pushed in. 4. Check whether the blade of the hopper is too tight. The blade is too tight and the resistance of the material constitutes the addition of the transmission load of the mixing motor, causing the transmission bump to break or the motor to burn. Efficiency and service life of the equipment are inseparable from daily maintenance and use, and the staff must not be underestimated. When the problem of poor drying occurs, the problem should be found from the following three aspects: 1.Causes and troubleshooting of common failures of plastic dryersFault 1: The dehumidification function cannot be activatedReason 1: The filter is blocked. Solution: Strictly follow the cleaning instructions to clean the filter. Reason 2: The outlet and inlet are blocked. Solution: Clean up the blockage. Trouble 2: Dehumidification dryer does not work Reason 1: The power cord is not properly connected. Solution: Connect the plug and socket well. Reason 2: The water tank is full or not put in place. Solution: Drain the water in the water tank or put it in a standard location. Fault 3: No wind enters the desiccant dryer? Reason: The filter is blocked. Solution: just clean the filter. Failure 4: The dehumidification dryer is very noisy during operation Reason 1: The machine is not placed stably. Solution: Place the desiccant dryer in a flat and firm position. Reason 2: Noise caused by clogged filter. Solution: just clean the filter. Also need to pay attention: if the desiccant dryer has a major failure, it is best to find professional maintenance personnel to repair it, so as to avoid further damage 2.Plastic dryer Dry air pathIn the drying air circuit, the drying temperature should be detected at the inlet of the silo to compensate for the heat loss of the dryer in the hose. The air temperature at the inlet of the silo is low, which may be due to improper adjustment of the controller and lack of insulation layer, or the heater element, heater current contactor, thermocouple or controller have failed. In addition, it is also important to monitor the drying temperature throughout the drying process and observe the temperature fluctuations during desiccant replacement.If the material is not properly dried after coming out of the dryer, you should check whether the drying bin has enough space to provide sufficient and effective drying time. The effective drying time refers to the time when the particles are actually exposed to the appropriate drying temperature and dew point. If the residence time of the granules in the silo is insufficient, proper drying cannot be achieved. Therefore, attention should be paid to the size and shape of the granular material or crushed material, which will affect the bulk density and residence time of the dried material. A twisted hose or a clogged filter can restrict airflow and affect the performance of the dryer. Therefore, if the dryer does not find such problems, it is impossible to judge whether the airflow is sufficient. Here, there is a quick, simple and accurate method to detect whether the airflow of the dryer is sufficient, that is, to measure the vertical temperature curve of the material in the drying bin. It is assumed that the drying time recommended by the material supplier is 4h, and the processing capacity is 100lb / h (1lb = 0.4536Kg). To determine whether the airflow of the dryer is sufficient, you can measure the temperature curve in the drying bin. Here, pay special attention to the temperature at 4h (400lb). If the temperature at the 400 lb level in the drying bin reaches the set value, then the air flow can be considered sufficient. If only the materials at 1h, 2h or 3h in the drying silo are fully heated, it means that the gas flow cannot complete the heating and drying of the materials at the predetermined yield. Insufficient heating may indicate that for this productivity, the drying silo is too small, or the air flow is restricted due to clogged filters or damaged hoses. If the air volume is too large, there will be problems, which not only waste energy, but also cause the temperature of the return air to be high and destroy the performance of the desiccant. The return air filter can prevent the filamentous material from contaminating the desiccant and affecting its hygroscopic performance. These filters must be kept clean to ensure adequate airflow. When the drying air comes out of the top of the dryer, most of the heat has been released. When the desiccant temperature is in the range of 120oF ~ 150oF, most dryers can work efficiently. If the return air overheats the desiccant, it will reduce its ability to adsorb moisture in the dry air. Always check the return air temperature of the dryer. When the temperature of the return air is high, it may indicate that for this productivity, the size of the dryer is too large, or the temperature when the material enters the drying bin is high, for example, PET has crystallized before drying, or only certain materials (such as PET ) The drying temperature is higher than the normal temperature range. In order to prevent the return air temperature from becoming high, as long as a heat exchanger is installed on the return air path, it can ensure that the desiccant can effectively remove the moisture in the dry air. 3.Plastic dryer Regeneration and cooling of desiccantThe moisture absorption capacity of the desiccant is limited, so the moisture it absorbs must be removed by regeneration. The process is: when the ambient air is sucked in, it enters the blower through a filter and is then sent to a group of heaters. The heated air passes through the desiccant bed. When the temperature of the desiccant rises, the adsorbed moisture is released. When the hot air is saturated with water vapor, it is discharged into the atmosphere. The high-temperature regenerated desiccant must be cooled before returning to the drying loop to restore the desiccant's moisture absorption function.The dew point reading can help find some problems, so the dry air dew point value should be monitored throughout the drying process. The dew point reading of the dryer during normal operation should be a straight line in the range of 20oF ~ 50oF. Of course, the small fluctuations caused by the replacement of the desiccant are normal. If the dryer is operating normally, the dew point at the dry air inlet should be at least 30oF lower than the dew point at the return air outlet. On the other hand, after the desiccant was replaced, the dew point peaked immediately, indicating that the desiccant was not sufficiently cooled before being placed, making it unable to absorb moisture well. After cooling, the dew point of the desiccant will drop to the normal standard. If the desiccant is not properly cooled, the temperature will peak, and the sudden temperature change will reduce the drying ability of the desiccant on heat-sensitive materials such as ionomers, amorphous polyester and certain nylon brands. If the dew point reading is normal after the desiccant bed is replaced, but the dew point rises quickly before the desiccant drying cycle ends, it means that ambient air may have entered the closed air path, causing the desiccant to absorb moisture prematurely. Another possibility is that the desiccant regeneration is incomplete or contaminated. If the dew point reading and the return air dew point reading are close, it indicates that the regeneration air circuit is completely invalid or the desiccant is seriously polluted. Plastic dryer Operation guide1. Before starting up, check the power distribution of all equipment and pipelines before work. If there are hidden dangers, remove them in time;2. Clean the air inlet filter of the heater; 3. When the temperature of the imported heat transfer oil of the main engine rises to 100-120℃, the induced air can be started; 4. The inlet temperature of the cloth bag reaches 70℃ or higher, which can be opened for stirring, stirring, and the number of rotations; 5. Air pressure: main machine inlet 6-10Mpa, cloth bag inlet, main machine outlet 20-26Mpa, cloth bag outlet 36-40Mpa; 6. Unloading starts within 15 minutes when starting up and feeding, and the unloading cannot be stopped for whatever reason, until the material in the bag box is unloaded after shutdown; 7. Each shift must have a dedicated person to watch the instrument on the panel, and if there is any abnormality, and find it out in time, the watcher cannot leave without authorization until it stops; 8. The feeder should carefully observe the material during feeding to avoid foreign matter in the material and cause accidents; 9. In normal work, the temperature of the heat transfer oil inlet should not exceed 250℃, otherwise it will be opened and closed immediately to cool down; 10. When you hear noise in the host during work, stop it immediately, open the side door of the host, cool down and use a magnetic stick or touch it to clean out the foreign objects; 11. During the work process, if there is a sudden power failure, immediately close the thermal oil valve, open and close, and open the side door of the host to cool down; 12. When a power outage comes in, the cloth bags should be cleaned first, and when the induced air is turned on, open the side door of the host to observe whether there are sparks. If necessary, spray with water (mist); 13. If there is a sudden change in the radiator oil bag pipeline (severe oil leakage, fire, etc.), the main oil guide valve should be closed immediately, and on-site fire fighting should be carried out immediately, and the boiler should be notified to cool down; 14. If sparks and explosions are found in the main engine and the bag box, immediately stop the induced air, open the closed valve, and close the oil guide main line valve 15. When you find sparks in the bag, you should hurry up. Unload the fired material, flush the bag with water, and control the amount of water to prevent the bag from being damaged due to excessive water level. Plastic dryer operating instructions1. PurposeStrengthen equipment management, avoid operating errors in the production process, reduce personal injury accidents, and ensure safe and effective Operation drying system is running. 2. area It is suitable for the operation equipment and its operators of the drying system in the workshop. 3. Operating procedures  3.1 Dehumidifying dryer Preparation before starting 1) Before starting the dryer, check whether the circulating water is normal. 2) Check whether the connecting parts and the nuts of the sealing section are loose, if they are loose, please tighten the nuts to compress the packing And timely reinforcement. 3) Check whether the connection of the meter is normal and whether it can operate normally. 3.2 Boot steps 1) Turn on the power and press the Dryer/Reset button for 3 seconds to turn on equipment; 2) Dehumidifying dryer Temperature setting: press the SV/ key and use the up and down arrow keys Set the temperature, press the SV/ key again after setting to confirm recognize; 3) Adding raw materials: press the Drying Hopper button, Add raw materials to the material tube, press again to stop; 4) Raw material supply: press the NO.1 button to supply the barrel of the injection molding machine Raw materials, press again to stop. 3.3 Shutdown steps  Turn off the raw material supply, press and hold the Dryer/Reset button for 3 seconds to stop the equipment and cut off the power supply. 4. Precautions during use 4.1 Input of raw materials: the following points should be noted before adding raw materials a). Close the valve of the manual unloading port to prevent feeding. Raw materials Sprinkle, as shown in Figure 1; b). Confirm that the drying cylinder is clean and free of residual materials to avoid mixing; c) When changing the color of raw materials, (such as black raw materials for white raw materials) application Use cotton cloth and medical alcohol to carefully clean the drying cylinder and raw material delivery pipeline to avoid Avoid products with different colors and other defects; d). When adding raw materials each time, make sure that a magnetic rack is put in the drying cylinder. and Ensure that the magnetic stand is clean and free of adsorption (as shown in Figure 2 and Figure 3); 4.2. The supply of raw materials: when the injection molding machine is automatically supplied with materials, the manual Seal the material opening 4.3. Record filling: Every time raw materials are added, corresponding records should be filled in. Obviously record the raw materials Model, quantity, drying temperature, time and other parameters; 4.4. Drying quantity of raw materials: when receiving raw materials for drying, try to receive a suitable quantity of raw materials Dry it. Avoid running out of raw materials and repeated drying. When the production task is completed, the original The materials are discharged and returned to the warehouse. To ensure the accuracy of raw material inventory. 5. Dehumidifying dryer Equipment maintenance 1) Check whether the hose has fallen off, broken or leaked every month. 2) Check whether the screws and nuts of each part of the device are loose every month. 3) Every 3 months, check whether the terminals in the control box and the wiring connection part of the device are loose. 4) Clean the delivery filter every 3 months and replace the filter if necessary. 5) Check and repair the main motor every 6 months.

|

plastic Dehumidifying dryer technology and maintenance |

| Dehumidification dryer | gravimetric blender | plastic granules mixing machine |

|

|

|

| Phone/WeChat: | +86-13669807274 | Whatapp: | +86-13669807274 | E-mail: | wto-btb@wto-btb.com |

| Website name:plastic Dehumidifying dryer Copyright:plastic Dehumidifying dryer |

| Search industry:plastic Dehumidifying dryer,plastic dryer ©2007-2029 @ |